Unveiling the Potential of Lab Scale High Pressure Reactors: A Detailed Insight

The realm of chemical synthesis and material science is witnessing a significant transformation, thanks to the advancements in lab scale high pressure reactors. These sophisticated pieces of equipment, crafted meticulously by high pressure reactor manufacturers, are pivotal in conducting experiments that require precise control of pressure and temperature. This blog delves deep into the world of lab scale high pressure reactors, exploring their design, applications, benefits, challenges, future prospects, and safety considerations.

The Design of Lab Scale High Pressure Reactors

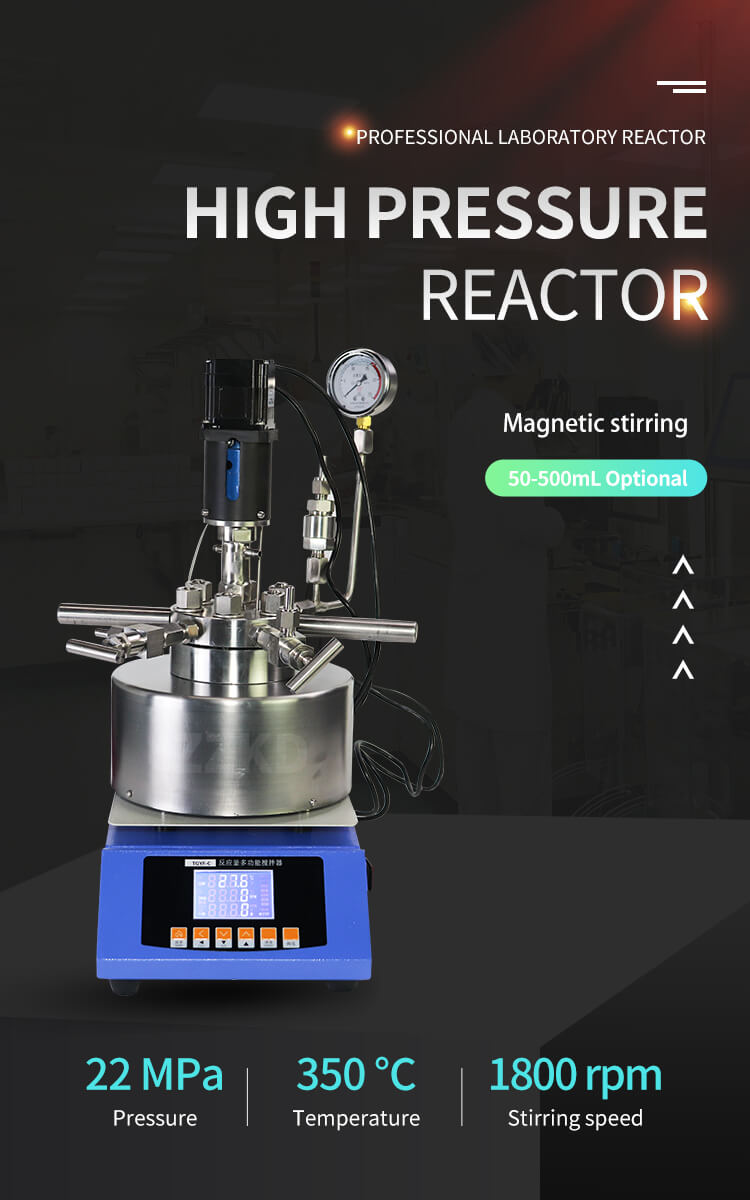

Lab scale high pressure reactors are ingeniously designed to withstand extreme conditions. Typically made from robust materials like stainless steel or special alloys, they can handle pressures ranging from a few bar to several hundred bar. The core component is the pressure vessel, which is often equipped with temperature control systems, magnetic or mechanical stirrers, and various ports for adding or removing substances.

The control system is another critical aspect. It ensures precise regulation of pressure, temperature, and stirring speed, which is crucial for reproducible results. Advanced models also feature computer interfaces for monitoring and data logging, enhancing the ease of experimentation and analysis.

Applications in Research and Industry

The versatility of lab scale high pressure reactors is evident in their wide range of applications. In the pharmaceutical industry, they are used for hydrogenation reactions, a key step in drug synthesis. In material science, researchers rely on these reactors for developing new polymers and nanomaterials under controlled high-pressure conditions.

Moreover, they play a crucial role in energy research, particularly in the study of biofuels and hydrogen storage materials. The ability to simulate high-pressure environments is essential for understanding material behavior and reaction kinetics in these fields.

Advantages Over Traditional Reactors

One of the primary advantages of lab scale high pressure reactors is their ability to reach conditions unattainable in conventional laboratory reactors. This capability opens up new reaction pathways, potentially leading to more efficient processes and novel products.

Furthermore, these reactors often yield more accurate data due to their precise control over experimental conditions. This precision is crucial for developing scalable processes that can be transferred from the lab to industrial production.

Overcoming Challenges

Despite their benefits, working with lab scale high pressure reactors presents certain challenges. The high-pressure environment requires stringent safety measures and specialized training for operators. Additionally, the complexity of these systems can lead to higher initial costs and maintenance requirements compared to standard laboratory equipment.

Addressing these challenges involves a combination of proper training, adherence to safety protocols, and choosing reactors with robust safety features. Manufacturers are continually innovating to make these reactors more user-friendly and safer.

Future Prospects and Innovations

The future of lab scale high pressure reactors is bright, with ongoing advancements aimed at enhancing their capabilities. Innovations in materials technology are leading to reactors that can withstand even higher pressures and temperatures, broadening the scope of potential experiments.

Additionally, the integration of automation and artificial intelligence is set to revolutionize how these reactors are operated. Automated systems could lead to more efficient, reproducible, and safer operations, significantly impacting research and development across various fields.

Safety First: Handling High Pressure with Care

Safety is paramount when working with lab scale high pressure reactors. These systems must be equipped with safety valves, rupture discs, and pressure relief systems to prevent accidents. Regular maintenance and inspections are crucial to ensure the integrity of the reactor.

Operators must be thoroughly trained in handling high-pressure equipment and should always adhere to established safety protocols. By prioritizing safety, researchers can harness the full potential of these powerful tools without compromising the well-being of personnel.

Conclusion: A Tool for Advancement

Lab scale high pressure reactors represent a significant leap forward in experimental capabilities. They offer unparalleled control over reaction conditions, opening new avenues in research and industrial applications. While challenges exist, ongoing innovations and a strong emphasis on safety continue to enhance their utility and accessibility. As high pressure reactor manufacturers continue to refine these devices, their impact on science and technology will undoubtedly grow, paving the way for groundbreaking discoveries and advancements.