Unveiling the Future of Chemical Synthesis: The High Pressure Teflon Reactor

In the ever-evolving world of chemical engineering and materials science, the development of efficient, safe, and cost-effective reactors is paramount. Among the most notable advancements in this field is the High Pressure Teflon Reactor, a technological marvel that is setting new benchmarks in chemical synthesis and industrial applications.

Revolutionary Design and Functionality

The High Pressure Teflon Reactor emerges as a groundbreaking solution, particularly in processes where chemical reactions require high-pressure environments. Constructed using Teflon, known for its exceptional chemical resistance and thermal properties, these reactors can withstand corrosive substances and extreme temperatures, making them ideal for a wide range of chemical reactions.

What sets the High Pressure Teflon Reactor apart is its ability to maintain stability under immense pressure, a crucial factor in numerous chemical processes. This ability not only enhances the efficiency of chemical reactions but also significantly reduces the risk of hazardous incidents, which is a common concern in high-pressure environments.

Applications Across Industries

The versatility of High Pressure Teflon Reactors is evident in their widespread use across various industries. In the pharmaceutical sector, these reactors are instrumental in synthesizing complex compounds under controlled conditions. Similarly, in the petrochemical industry, they play a pivotal role in catalytic processes, essential for fuel refinement and processing.

Moreover, the food and beverage industry benefits from these reactors in terms of flavor extraction and food preservation techniques. The high-pressure environment aids in extracting flavors from natural sources without degrading the quality, a process that traditional methods cannot achieve.

Advantages Over Conventional Reactors

One of the most significant advantages of High Pressure Teflon Reactors is their resistance to chemical corrosion. This feature extends the reactor's lifespan and reduces maintenance costs, offering a cost-effective solution for industries. Additionally, the Teflon coating ensures that the reactions are not contaminated, a critical aspect in pharmaceutical and food processing applications.

Another notable advantage is the energy efficiency of these reactors. The high-pressure environment accelerates reaction rates, thereby reducing energy consumption compared to conventional reactors. This feature not only cuts operational costs but also aligns with the global push towards sustainable and eco-friendly industrial practices.

The Role of High Pressure Reactor Manufacturers

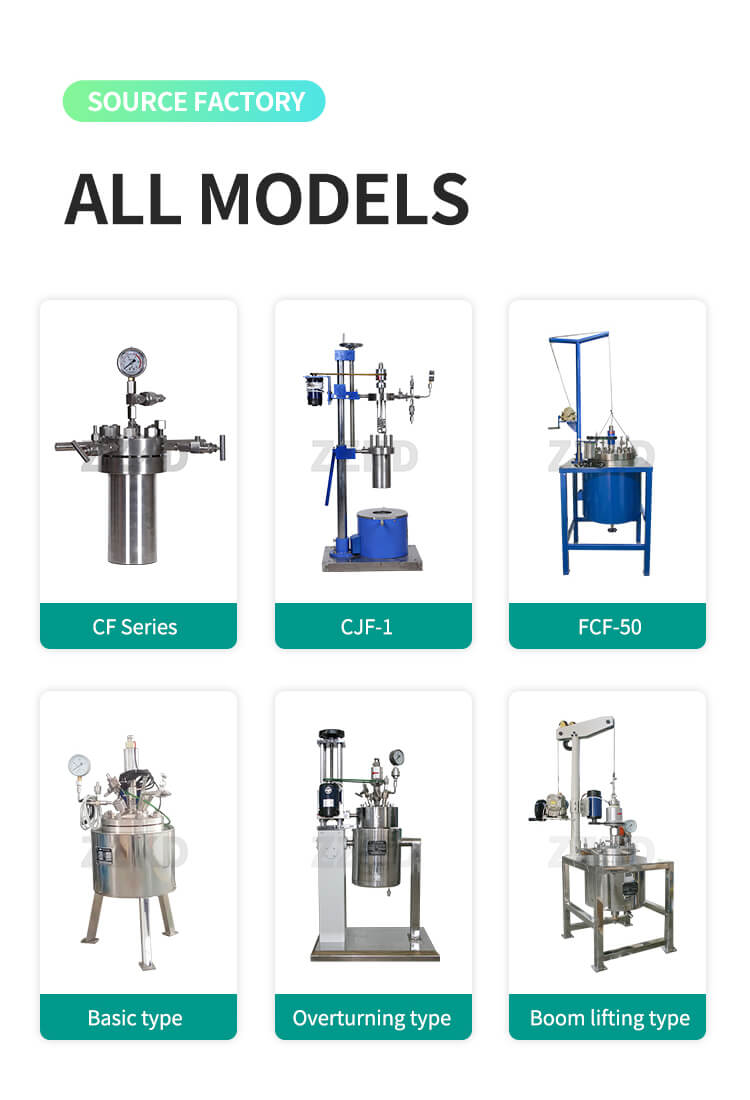

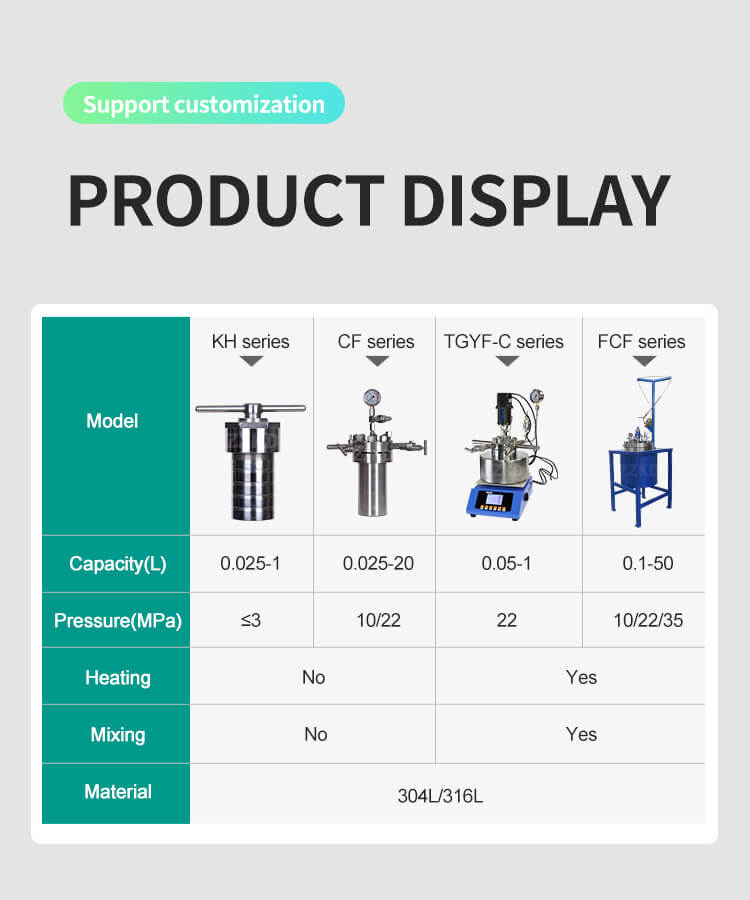

The manufacturing of High Pressure Teflon Reactors is a specialized field, requiring expertise in both chemical engineering and materials science. High Pressure Reactor Manufacturers play a crucial role in this ecosystem. These manufacturers are not just suppliers; they are partners in innovation, continuously working on enhancing the design, safety, and efficiency of these reactors.

Collaboration between manufacturers and end-users is vital. It ensures that the reactors are tailored to meet the specific needs of different industries, thereby maximizing their efficiency and applicability.

Challenges and Future Prospects

Despite their numerous advantages, High Pressure Teflon Reactors face challenges, particularly in terms of scaling up for industrial-scale production. Addressing these challenges requires ongoing research and development, an area where manufacturers and academic institutions are actively collaborating.

The future of High Pressure Teflon Reactors looks promising. With advancements in materials science and engineering, these reactors are expected to become more efficient, safer, and more adaptable to various industrial applications. As we move forward, High Pressure Teflon Reactors are poised to play a pivotal role in the advancement of chemical synthesis and industrial processing, marking a new era in the field of chemical engineering.

Conclusion

The High Pressure Teflon Reactor stands as a testament to the incredible strides being made in the field of chemical engineering. Its impact extends beyond just efficiency and safety; it symbolizes the potential of innovative thinking and collaboration across industries and disciplines. As we continue to explore the capabilities of these reactors, we open new doors to discoveries and advancements that will shape the future of industrial processing and beyond.