Understanding Industrial Spray Dryer Prices

Industrial spray dryers are vital equipment in various industries, from food production to pharmaceuticals and chemical manufacturing. When considering the purchase of an industrial spray dryer, one of the key factors to contemplate is the price. In this article, we will delve into the factors that influence industrial spray dryer prices, helping you make informed decisions for your business needs.

The Role of Capacity

The first and foremost determinant of an industrial spray dryer's price is its capacity. Capacity refers to the amount of liquid that can be processed and dried within a given time frame. Larger capacity spray dryers typically come with a higher price tag. The capacity you require depends on your production needs, and it's essential to strike a balance between cost and efficiency.

Capacity affects not only the initial purchase price but also operational costs, such as energy consumption and maintenance. Assess your production volume carefully to determine the right capacity for your business, ensuring that you're not overpaying for unused capabilities.

Material of Construction

Another crucial factor impacting the price of industrial spray dryers is the choice of materials for construction. These dryers can be constructed using various materials, each with its own set of advantages and costs. Common materials include stainless steel, mild steel, and glass-lined steel.

Stainless steel, known for its durability and resistance to corrosion, often comes at a higher price point. Mild steel may be more affordable but may require more frequent maintenance and may not be suitable for industries with strict hygiene standards. Consider your industry's requirements and budget when selecting the material of construction.

Drying Technology

The drying technology employed in an industrial spray dryer is a significant price influencer. Different drying technologies, such as centrifugal atomization, pressure nozzle atomization, and fluidized bed drying, come with varying costs. The choice of technology also affects the energy efficiency and drying precision of the equipment.

Centrifugal atomization, for instance, is often more expensive but offers precise control over particle size and shape. It's essential to assess your product's specific drying needs to choose the technology that best suits your requirements and budget.

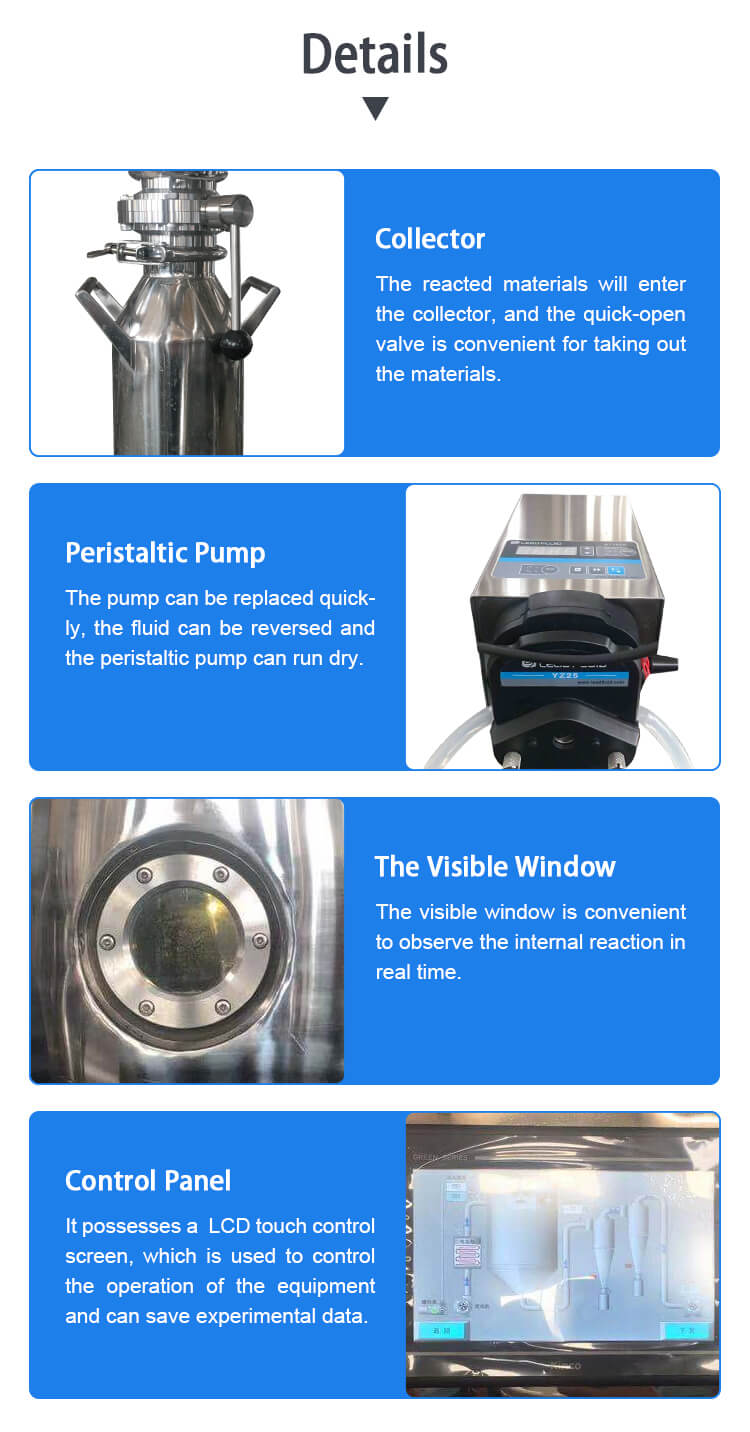

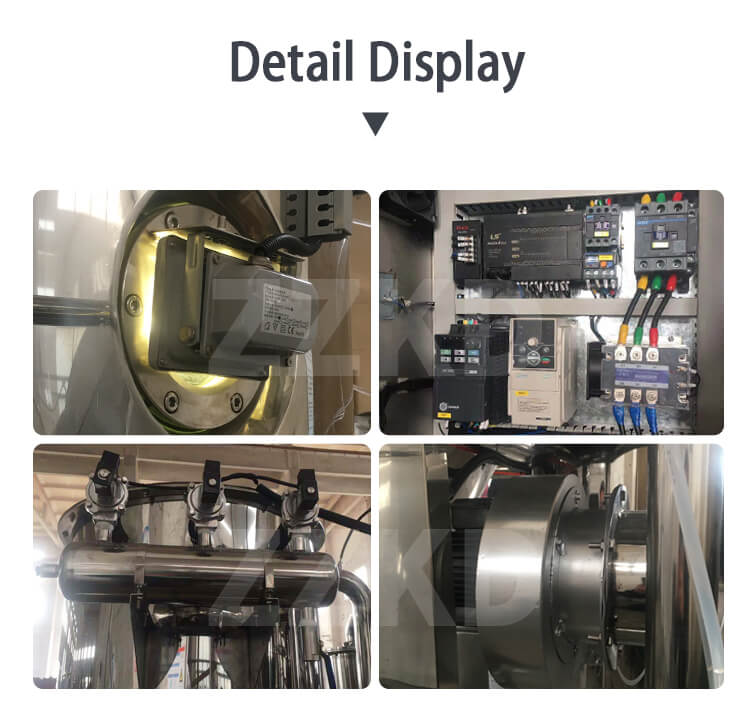

Control Systems and Automation

Modern industrial spray dryers come equipped with advanced control systems and automation features. These systems allow for precise control of various parameters, enhancing efficiency and product quality. However, such features can increase the upfront cost of the equipment.

Consider whether the benefits of automation, such as reduced labor costs and improved product consistency, outweigh the initial investment. Automation can also lead to long-term cost savings and improved productivity.

Additional Accessories and Customization

Industrial spray dryers often offer additional accessories and customization options to tailor the equipment to specific production needs. These can include options for temperature control, particle size control, and safety features. While these additions can enhance the functionality of the dryer, they can also add to the overall cost.

When evaluating customization options, carefully assess whether they are necessary for your production processes or if they can be added at a later date as needed. This approach can help you manage upfront costs while still meeting your long-term requirements.

Supplier and After-Sales Support

The choice of supplier also plays a significant role in the price of industrial spray dryers. Established suppliers with a reputation for quality and reliability may charge a premium for their products. However, this investment often comes with the assurance of after-sales support, technical assistance, and access to spare parts.

It's crucial to strike a balance between price and supplier reputation. Opting for a reputable supplier can ensure that your equipment operates smoothly and efficiently, reducing downtime and long-term operational costs.

In conclusion, industrial spray dryer prices are influenced by various factors, including capacity, material of construction, drying technology, control systems, customization, and supplier reputation. To make an informed decision, assess your specific production needs and budget constraints, considering the long-term operational costs and benefits. By carefully evaluating these factors, you can choose the right industrial spray dryer that meets your requirements without breaking the bank.