Spray Dryer Unit System: Transforming Liquid into Powder

The process of converting liquid substances into powdered form is a fundamental requirement in various industries. Spray dryer unit systems have become indispensable in achieving this transformation efficiently and economically. In this article, we will delve into the world of spray dryer unit systems, exploring their principles, applications, advantages, spray dryer price,and the role they play in industries worldwide.

Understanding the Spray Dryer Unit System

Spray drying is a widely used method for turning liquids, suspensions, or even slurry into dry powders. It involves four key steps: atomization, drying, particle separation, and powder collection. Atomization is the heart of the process, where the liquid feed is transformed into tiny droplets, greatly increasing the surface area for efficient drying.

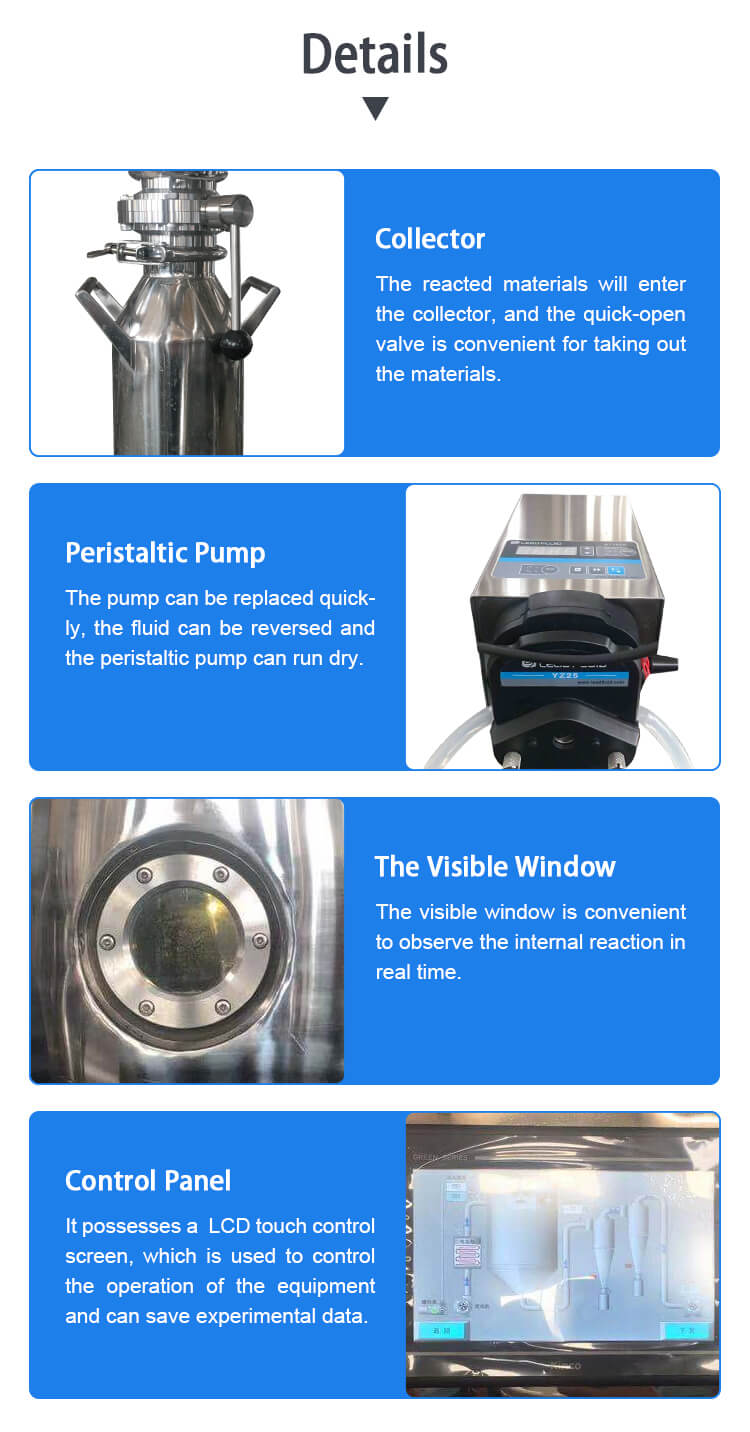

Components of a Spray Dryer Unit

A typical spray dryer unit system comprises several essential components. These include a feed system for delivering the liquid feed, an atomization system to create fine droplets, a drying chamber where hot air interacts with the droplets, and a cyclone or bag filter for separating the dried particles from the air.

Applications Across Industries

Food and Beverage Industry

Spray drying is extensively used in the food and beverage industry. It enables the production of powdered products like milk powder, coffee, and flavorings. The process preserves the flavor and nutritional content of the original liquid while extending its shelf life.

Pharmaceuticals and Biotechnology

In the pharmaceutical and biotechnology sectors, spray dryer unit systems are employed to create dry, stable forms of medications, vaccines, and enzymes. This facilitates easier storage, transportation, and dosage accuracy.

Chemical Manufacturing

Chemical manufacturers utilize spray drying for the production of various chemical compounds, including detergents, pigments, and catalysts. The controlled environment of the spray dryer ensures consistent product quality.

Advantages of Spray Dryer Unit Systems

Precision in Particle Size

Spray drying offers precise control over particle size, making it possible to tailor the characteristics of the final powder. This level of customization is essential in industries where product consistency is paramount.

Cost-Efficiency

Compared to other drying methods, spray drying is highly efficient, reducing energy consumption and production costs. The ability to recycle and reuse drying air further contributes to cost savings.

Preservation of Properties

One of the most significant advantages is the ability to preserve the properties of the original liquid, such as flavor, aroma, and bioactivity. This is crucial in industries like food and pharmaceuticals.

Worldwide Impact and Industry Demand

The demand for spray dryer unit systems has grown exponentially in recent years, driven by the need for efficient drying solutions across various sectors. ZZKD Machinery and Instrument Equipment Co., Ltd., a leader in laboratory equipment supply, has been at the forefront of meeting this demand.

ZZKD's Contribution

ZZKD, with its 13 years of export experience, has played a pivotal role in supplying high-quality spray dryer unit systems to customers worldwide. The company's commitment to manufacturing and developing top-notch equipment has earned it a trusted reputation in the industry.

Future Innovations

The future of spray dryer unit systems holds exciting possibilities. Advancements in automation and control systems are poised to enhance efficiency and precision further. Additionally, environmentally friendly drying technologies are on the horizon, aligning with global sustainability goals.

In conclusion, spray dryer unit systems are the backbone of industries that rely on converting liquids into powders. Their efficiency, precision, and versatility make them indispensable across various sectors. As technology continues to advance, we can expect even more innovations in the world of spray drying, revolutionizing industries and benefiting society as a whole.