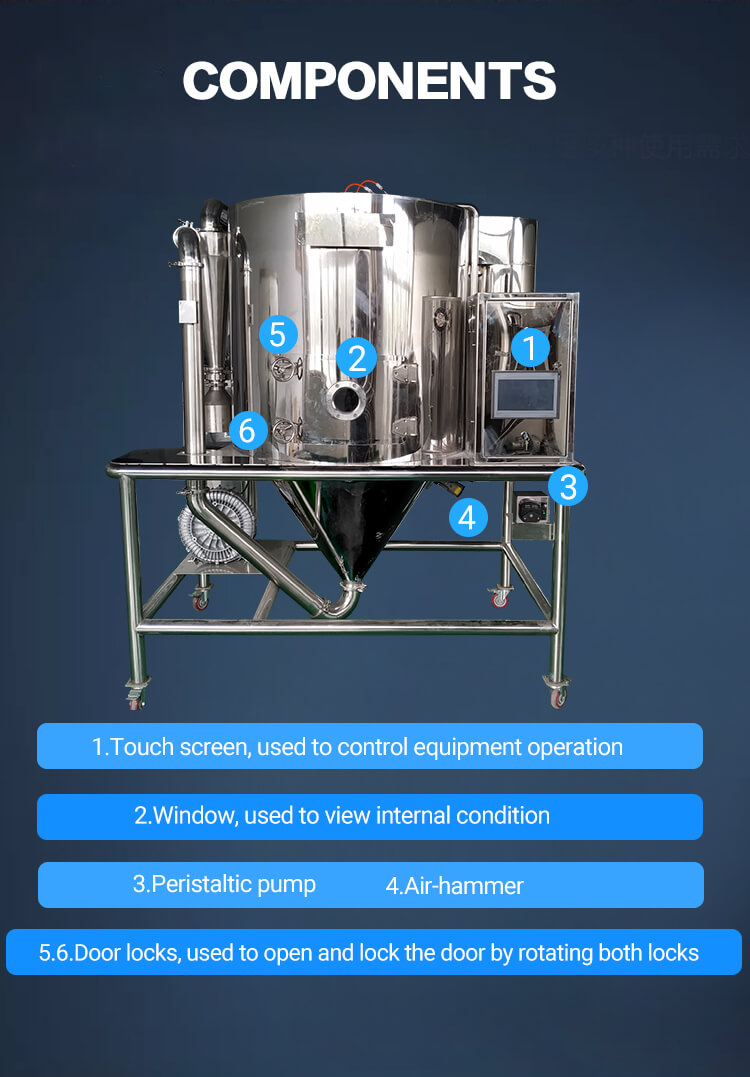

Spray Dryer Pilot Plant

The spray dryer pilot plant is a device that can complete drying and granulation at the same time. According to the process requirements, the pressure, flow rate, and size of the nozzle hole can be adjusted to obtain the required spherical particles in a certain size ratio. ZZKD provides a small spray dryer pilot plant and a small spray dryer price pilot plant in the laboratory, which can meet the different needs of customers, and welcome your consultation.

The spray dryer pilot plant is a kind of continuous atmospheric pressure dryer. The liquid material is sprayed into mist with special equipment, and it is dried in contact with hot air. It is used for drying some heat-sensitive liquids, suspensions and viscous liquids, as well as for drying fuels, intermediates, soap powders and inorganic salts, etc. The spray dryer pilot plant is suitable for the production of micro-particle powders in laboratories of universities, research institutes and food, pharmaceutical and chemical enterprises. It has broad-spectrum applicability to all solutions such as emulsions and suspensions, and is suitable for drying heat-sensitive substances such as biological Products, biological pesticides, enzyme preparations, etc.

The materials sprayed out by the spray dryer pilot plant are only subjected to high temperature when they are sprayed into mist-like particles, so they are only heated instantaneously, which can keep these active materials from being damaged after drying. Today, Jordan will take you to know about this spray dryer pilot plant produced by ZZKD.

How does the spray dryer pilot plant work?

Do you know which stages are included in the actual application of the spray dryer pilot plant?

The first stage is the atomization of the feed liquid, and the main purpose of this stage is to disperse the feed liquid into fine droplets. The reason for such treatment is mainly because after dispersing these liquids, a large surface area can be obtained, so it can be fully mixed with the hot air in the spray dryer pilot plant. In this way, the evaporation of water can be completed quickly in a short time.

The second stage is mainly to fully contact the dispersed mist droplets with hot air. In the spray dryer pilot plant, when the two are in the process of flowing contact, the heat and mass transfer, constant speed and deceleration stages of drying are actually being carried out continuously. It should be noted that in this process, we need to properly adjust the amount of liquid added and the temperature of hot air according to the specific conditions of the spray dryer test plant and the drying requirements, which can help to obtain dry powder or granular products.

The third stage is the separation and collection of gas-solid substances. In this stage, it is actually a process of separating and collecting the dried product from the hot air. It should be noted that at this time, we should consider the properties of the processed materials and the product yield to select the appropriate separation and collection method and spray dryer test plant equipment.

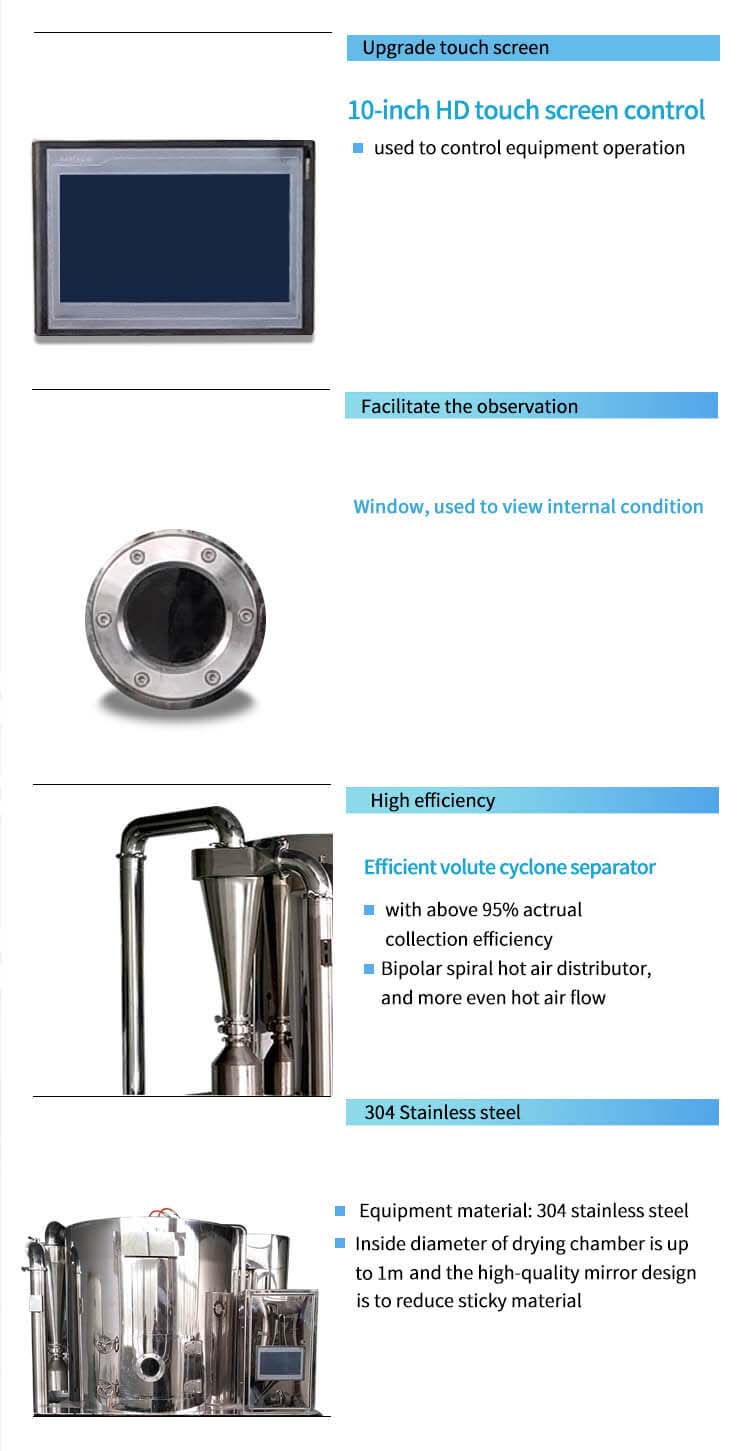

Due to the strong drying performance of the spray dryer test plant itself, it can not only complete the drying process in a very short time when performing drying treatment, but also adopts a sealed structure as a whole, which will not cause adverse effects on the site environment. It also has the characteristics of stable operation and low noise. Let's follow Jordan to learn more about the characteristics of this spray dryer pilot plant produced by ZZKD.

Features of spray dryer pilot plant:

1) Fast drying. After the material liquid is sprayed, the surface area is greatly increased. In the high-temperature air flow, 95%-98% of the water can be evaporated instantly, and the drying time is only a few seconds.

2) The co-current spray drying method can make the droplets and the hot air flow in the same direction. Although the temperature of the hot air is relatively high, because the hot air enters the drying chamber and immediately contacts the spray droplets, the indoor temperature drops sharply, while the wet bulb temperature of the material Basically unchanged, so it is also suitable for drying heat-sensitive materials.

3) Wide range of use. According to the characteristics of the material, it can be used in the laboratory spray dryer pilot plant, and most products with very different characteristics can be produced by this machine.

4) The airtightness of the entire operation is suitable for clean production areas. Since the spray drying operation is carried out in a closed tower, cross-contamination and dust flying are avoided, and it is suitable for the production of raw materials in the pharmaceutical industry, especially the production of sterile raw materials.

5) Since the drying process is completed in an instant, the particles of the finished product can basically maintain the approximate spherical shape of the liquid droplets, and the product has good dispersion, fluidity and solubility.

After drying, there is no need for crushing and screening, which reduces the production process and improves product purity. The particle size, bulk density and water content of the product can be adjusted by changing the operating conditions within a certain range, and the control and management are very convenient.

The above content is the detailed situation of the ZZKD spray dryer test plant introduced by Jordan. I hope you can provide some help when you choose to buy a spray dryer test plant and encounter problems in using the spray dryer test plant after reading it.

ZZKD Machinery Instrument Equipment Co., Ltd. is a comprehensive manufacturer specializing in R&D, production, sales, laboratories, biochemical and pharmaceutical equipment, especially transevaporators, glass reactors, vacuum pumps, etc. 13 years of production and export experience and a series of ISO9001 and CE certificates, with warehouses in the United States, Spain and Thailand.

A good after-sales service

1. 24-hour online customer service to provide reasonable solutions.

2. Factory direct sales, fast arrival, 1-2 days from warehouse.

3. Video communication to guide problems that arise during use.

4. Professional after-sales department, after-sales return visit, maintenance service.

If you want to know about our products, or want to buy our equipment, please feel free to contact us, ZZKD will provide you with the best price for the spray dryer pilot plant.