Short path distillation equipment and molecular distillation machine difference

The short-path molecular distillation equipment adopts its high vacuum and low distillation temperature during use, the equipment can have a short residence time, the whole equipment has high evaporation efficiency, and can be continuously distilled during use. materials are separated.

Short path ditilation unit can effectively remove low molecular substances in its liquid to a certain extent, such as its odor and organic solvents. The equipment selectively distills out the target product and removes other impurities, so it is regarded as a protector of natural quality and returnees.

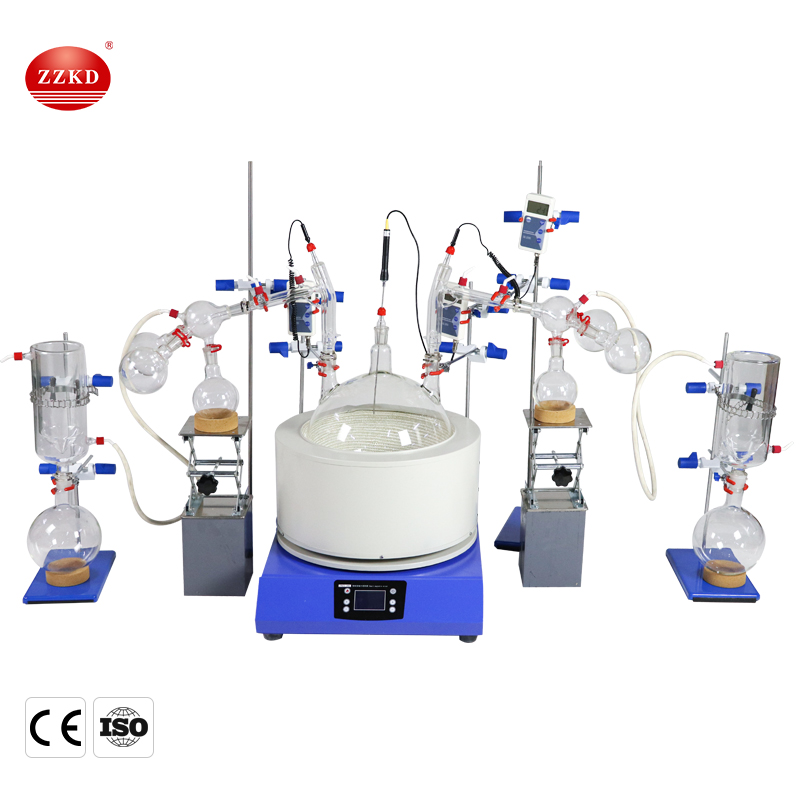

2l short path distillation kit

The short-range molecular distillation equipment can realize the physical process that the traditional separation method cannot achieve when it is used. Therefore, it is widely used as a means of deodorization, decolorization and purification in the separation of these high-priced plant materials. The wall of the evaporator is self-cleaning and polluting. Small and easy to clean.

The short-range molecular distillation equipment will effectively install a condenser inside on the basis of the scraper evaporator. When in use, when the feed mixture is heated, when a light substance molecule moves to a certain distance, it will effectively hit the condenser. is condensed into liquid and separated out.

In the short-path molecular distillation equipment, the vapor phase of light substances is condensed inside, which will make the vacuum pressure drop small and maintain a high degree of vacuum in the equipment to a certain extent. The special structural design of short-path distillation allows the operating pressure Achieving a low operating vacuum, the experimental-scale equipment vacuum can reach 0.1Pa,

During the operation of the short-path molecular distillation equipment, the temperature is much lower than the boiling point of the material. Since the equipment adopts its central condensation, the cross-sectional area of the material flow is equal to the evaporation surface, which will cause a slight difference between the evaporator and the condenser. pressure drop.

When molecular distillation operates at a certain temperature, the lower the pressure, the greater the degree of average freedom of the gas molecules generated. When the pressure of the evaporation space of molecular distillation is low, the condensation surface will be close to the evaporation surface.

Molecular distillation effectively vaporizes the vapor molecules from the evaporation surface, which can effectively not collide with other molecules effectively. The equipment can directly reach its condensation surface and condense. The molecular distillation in the equipment is a special liquid, which is different from the traditional one. Distillation relies on its boiling point difference to separate.

Molecular distillation systems

During the operation of molecular distillation equipment, the liquid mixture will be effectively heated along the flow of the heating plate. Due to the different degrees of freedom of its light and heavy molecules, the molecules of different substances will move at different distances after effectively escaping from the liquid surface. If it can be properly set on a condensing plate, its light molecules can reach the condensing plate and be condensed and discharged, so that the heavy molecules cannot reach the condensing plate and be effectively discharged along the mixing, so that the purpose of material separation can be effectively achieved to a certain extent. .

The lower the temperature of molecular distillation equipment, the effective operation of molecular distillation is at a temperature far below the boiling point, and the purpose of separation can be effectively achieved only if there is a temperature difference, which is the essential difference between conventional distillation and molecular distillation.

The vacuum degree of molecular distillation is relatively high, and a relatively high degree of vacuum can be obtained inside. Generally, molecular distillation operates under low pressure, so the material is not easy to be damaged by oxidation. The heating time of the material is short, and it stays at the distillation temperature general time.

The above is the difference between short path distillation and molecular distillation. If you have needs, you can contact Zhengzhou Keda Machinery Equipment Co., Ltd. For decades, Zhengzhou Keda Machinery Equipment Co., Ltd. has been committed to the production and manufacture of laboratory instruments and pipe fittings.

If you want to know about our products, or want to buy our instruments, please feel free to contact us, we will be happy to help you.