Rotary Evaporator Glassware

We are the domestic manufacturer of rotary evaporator glassware, we have 2L rotary evaporator, 3L rotary evaporator, 5L rotary evaporator and 100L equal capacity rotary evaporator.

Rotary evaporator glassware is a widely used evaporation instrument in laboratories. Rotary evaporator glassware is suitable for reflux operations, rapid evaporation of large quantities of solvents, concentration of minor components, and reaction processes requiring stirring. The rotary evaporator glassware system can be sealed and decompressed to 400~600mmHg; the solvent in the distillation bottle is heated by a heating bath, and the heating temperature can be close to the boiling point of the solvent; at the same time, the rotary evaporator glassware can also rotate at a speed of 50~160rpm, so that The solvent forms a thin film, increasing the evaporation area. In addition, under the action of the high-efficiency cooler, the hot steam can be liquefied quickly and the evaporation speed is accelerated.

Rotary evaporator glassware:

Rotary evaporator glassware mainly includes: condenser, rotary bottle, receiving bottle, four-way bottle, feed piston and glass through shaft. Let's introduce these products below:

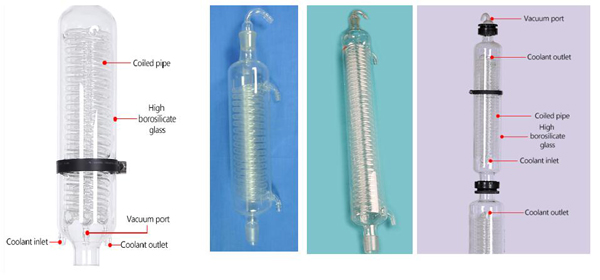

1. Condenser

Function: The position of the inlet and outlet is different, the position of the vacuum pumping port is different; there are main and auxiliary condensers; recovery rate-evaporation rate.

2. Spin bottle

Function: Reaction container for materials. The capacity is different, and the general caliber is different. The glass part is made of GG17 high borosilicate glass.

3. Receiving bottle

Function: used for receiving after material reaction. The capacity is different, the general caliber is different, and the small-capacity receiving bottle below 3L has no discharge port. There is a discharge port for more than 5L, and there are more air vents and vacuum ports on the receiving bottle of more than 5L.

4. Four-way bottle

5. Feeding piston (with PTFE tube)

Different models, different lengths.

6. Glass shaft

Diameter and length vary by model.

Rotary evaporator precautions:

1. The assembly of the glassware of the rotary evaporator should be handled with care, and it should be cleaned, wiped or dried before assembly.

2. Before installation, a layer of vacuum grease must be applied to each grinding port, sealing ring and joint.

3. Water must be added before the heating tank is powered on. Anhydrous dry heating is not permitted.

4. The glassware of the rotary evaporator must be screwed into the safety hole to prevent damage to the flask.

5. If the glassware of the rotary evaporator cannot be vacuumed, check the joints, whether the joints are sealed with sealing rings, whether the sealing surface is effective, whether the main shaft and the sealing ring are coated with vacuum grease, whether the vacuum pump and its hoses are leaking, the glass Whether there are cracks, cracks, damage, etc.