Rotary Evaporator: Essential Parts and Applications

The rotary evaporator is a crucial tool in the field of chemistry, widely used for the efficient separation and concentration of liquid samples. Its versatility and effectiveness make it an indispensable piece of equipment in laboratories, research institutions, and industrial settings. In this article, we will explore the various parts of a rotary evaporator, discuss its uses, and delve into an application case that highlights its practical significance. So, let's dive into the world of rotovap for sale and discover how they revolutionize the process of distillation.

I. Understanding the Rotary Evaporator

A. Definition and Basic Principles

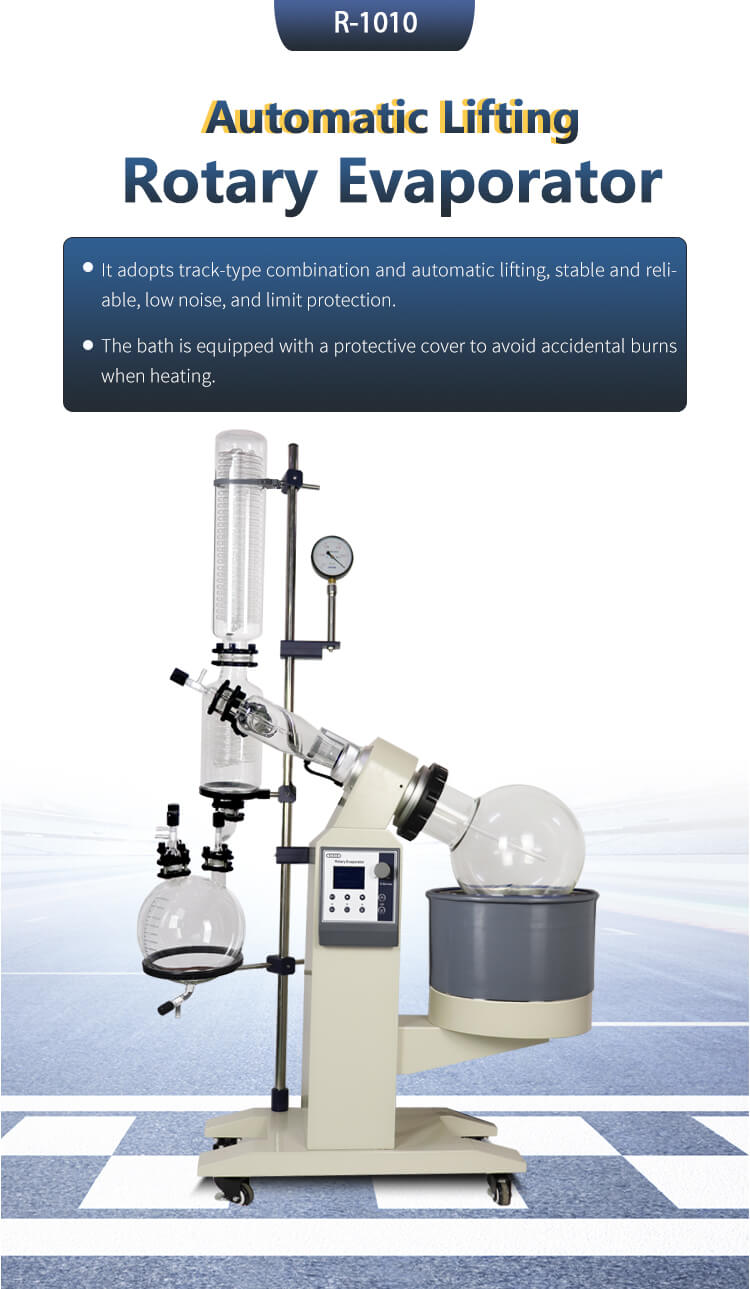

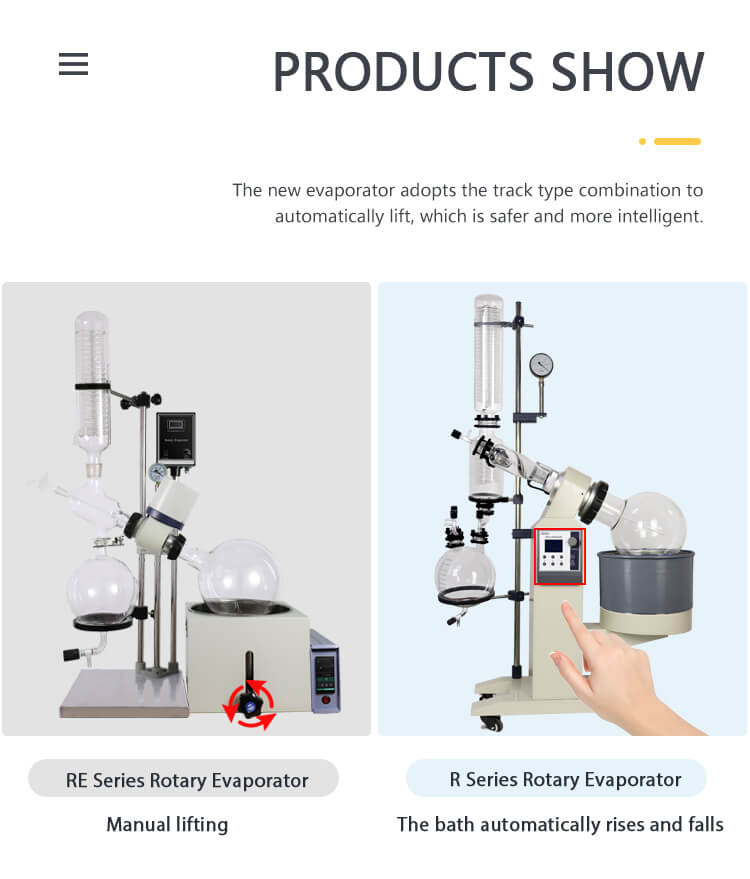

The rotary evaporator, also known as a rotovap or rotavapor, is a laboratory instrument used for the gentle and efficient evaporation of solvents from samples under reduced pressure. It operates on the principle of evaporation by utilizing heat, vacuum, and rotation. By rotating the sample flask while applying heat and vacuum, the rotary evaporator facilitates the evaporation process, allowing for the separation of volatile components from the sample solution.

B. Essential Parts of a Rotary Evaporator

1. Flask and Condenser

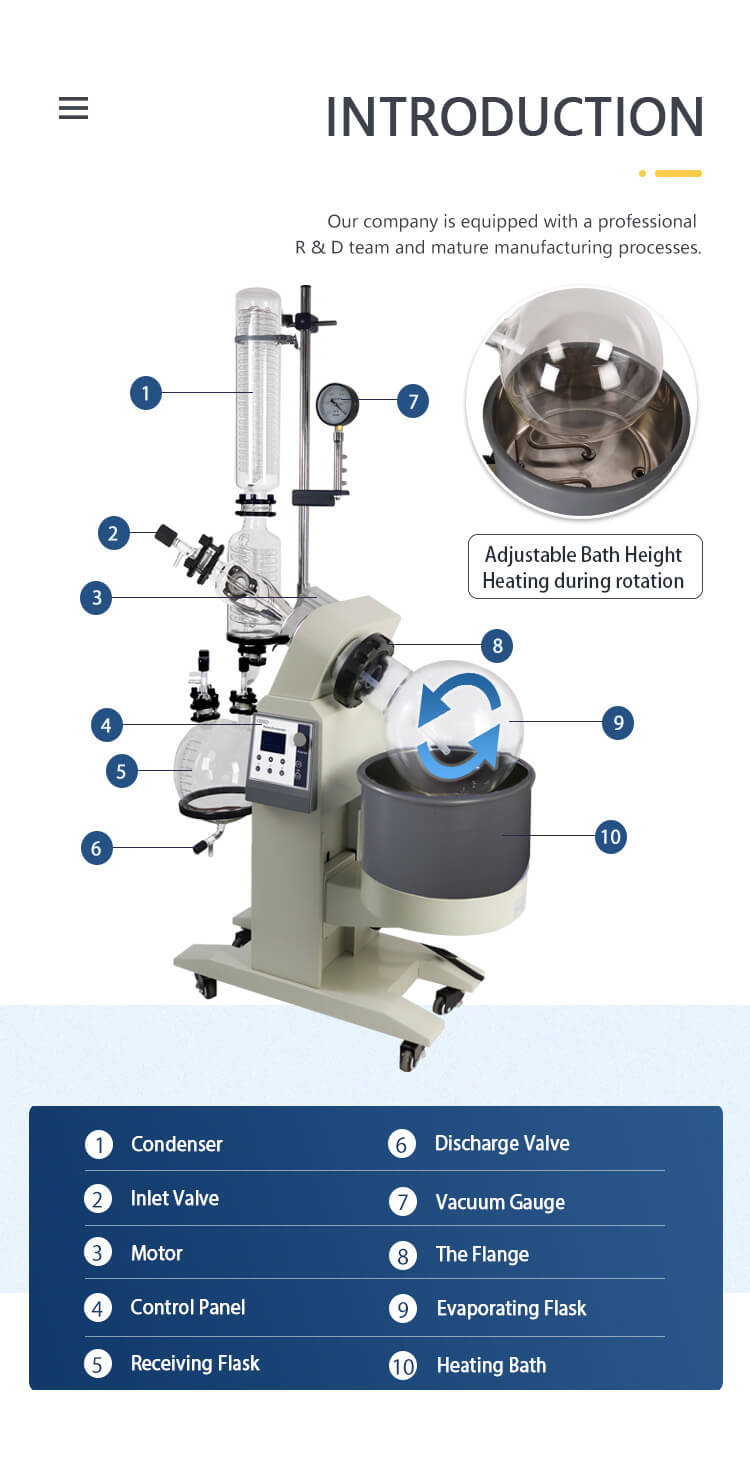

The primary components of a rotary evaporator are the flask and condenser. The sample to be evaporated is placed in the flask, which is typically made of borosilicate glass to withstand high temperatures. The condenser, usually a coiled glass tube, is responsible for cooling the vapor from the sample, causing it to condense and return to the liquid phase.

2. Water Bath and Heating Bath

To provide heat for the evaporation process, a water or heating bath is employed. The water bath, filled with temperature-controlled water, surrounds the flask and ensures uniform heating. Alternatively, a heating bath can be used, which directly heats the sample flask. The choice of bath depends on the specific requirements of the experiment.

3. Rotating Motor and Drive

The heart of the rotary evaporator lies in its rotating motor and drive mechanism. This setup allows the flask to rotate continuously, enhancing the evaporation rate by increasing the exposed surface area of the sample to the vacuum and heat.

4. Vacuum Pump

To achieve the desired pressure within the system, a vacuum pump is used. The pump creates a vacuum, reducing the boiling point of the solvents in the sample, thereby facilitating their evaporation at lower temperatures.

II. Applications of Rotary Evaporators

A. Solvent Recovery

One of the primary uses of rotary evaporators is solvent recovery. In industries where large quantities of solvents are used, such as pharmaceuticals or chemical manufacturing, rotary evaporators play a crucial role in the efficient and cost-effective reclamation of valuable solvents. By evaporating the solvents under controlled conditions, the rotary evaporator allows for their collection and reuse, minimizing waste and reducing production costs.

B. Essential Oil Extraction

The pharmaceutical and perfume industries heavily rely on the extraction of essential oils from natural sources. Rotary evaporators offer an ideal solution for this application. By evaporating the solvent from the extracted oil, the rotary evaporator ensures the preservation of the aromatic compounds, resulting in high-quality essential oils.

C. Concentration of Samples

In research laboratories, it is often necessary to concentrate liquid samples for further analysis or purification. The rotary evaporator enables rapid concentration of samples by removing the solvent under controlled conditions, thus increasing the concentration of the desired compound. This process saves time and resources while ensuring accurate results.

D. Environmental Analysis

Rotary evaporators are extensively employed in environmental analysis, particularly for the analysis of volatile organic compounds (VOCs). By evaporating the sample extracts and separating the analytes from interfering substances, the rotary evaporator aids in the accurate detection and quantification of VOCs present in environmental samples.

III. Application Case: Concentration of Natural Extracts for Density Determination

To illustrate the practical significance of rotary evaporators, let's consider a specific application case where a rotary evaporator is used for the concentration of natural extracts to determine their density.

In a research project investigating the composition of a medicinal plant, a natural extract was obtained through solvent extraction. To determine the density of the extract, it needed to be concentrated to a specific range (between 0.5% and 3% density). A rotary evaporator was employed to facilitate this process.

The researchers placed the extract in the flask and set the rotation speed and bath temperature according to the solvent's boiling point. By applying vacuum using a vacuum pump, the pressure within the system was reduced, lowering the boiling point of the solvent. As a result, the solvent evaporated at a lower temperature while leaving behind the concentrated extract in the flask.

The researchers monitored the process, adjusting the parameters as needed to achieve the desired density range. Once the concentration reached the desired level, they removed the flask and determined the density of the concentrated extract, providing valuable data for their research.

This application case highlights the precision and efficiency of rotary evaporators in concentrating samples to meet specific requirements, enabling researchers to perform accurate analyses and draw meaningful conclusions.

IV. Conclusion

Rotary evaporators are indispensable tools in the world of chemistry and scientific research. With their ability to facilitate efficient evaporation and concentration of samples, they have found applications in various fields, including solvent recovery, essential oil extraction, sample concentration, and environmental analysis.

Understanding the different parts of a rotary evaporator, such as the flask, condenser, rotating motor, and vacuum pump, allows scientists and technicians to optimize their usage and achieve desired outcomes. By harnessing the power of heat, vacuum, and rotation, the rotary evaporator streamlines the process of distillation, revolutionizing the way we separate and concentrate liquids.

As technology advances, rotary evaporators continue to evolve, offering greater efficiency and enhanced capabilities. Their role in scientific advancements and industrial processes remains critical, empowering researchers and professionals to push the boundaries of knowledge and innovation.