Quick Path Distillation Kits & Equipment For Sale

Short-path distillation gear from short-path distillation manufacturers can be found in 2L, 5L, 10L, and 20L short-path distillation units. These short-path distillation items are extremely resistant to corrosion and high temperatures. Since the short-path distillation system is a short-path distillation technique, it can be used as a extraction device for hemp oil to save tons of prices and improve recovery. As a manufacturer of laboratory gear, short path ditilation unit is certainly one of our firm's major tools.

Since the space traveled by the evaporated component could be very short, regular a quantity of centimeters, it's referred to as brief path distillation. The advantage is that the heating temperature can be considerably lower than the boiling level of the liquid at standard pressure, and the distillate only has to journey a brief distance earlier than condensing. This method is used for compounds which are unstable at excessive temperatures as a outcome of it allows a decrease boiling temperature for use. A quick path ensures that little compound is misplaced on the perimeters of the apparatus.

There are basically two forms of distillation processes, corresponding to brief path distillation and fractional distillation processes. Depending in your nature, you have to select the best short-path distillation or fractionation unit.

Other greater boiling point materials strikes downwards beneath the pressure of gravity and turbulence attributable to the wiper blades. Thus, the distillation is accomplished and crude materials gets separated. Short path distillation is a distillation method that utilizes reduced stress to permit elements with decrease boiling factors to journey a brief distance and condense onto a condenser column for distillation functions. Because the vaporized elements journey a brief distance, usually only some centimeters, it is calledshort path distillation equipment. A brief path fractionator package is a distillation technique that includes the distillate touring a brief distance, often just some centimeters, normally underneath lowered strain.

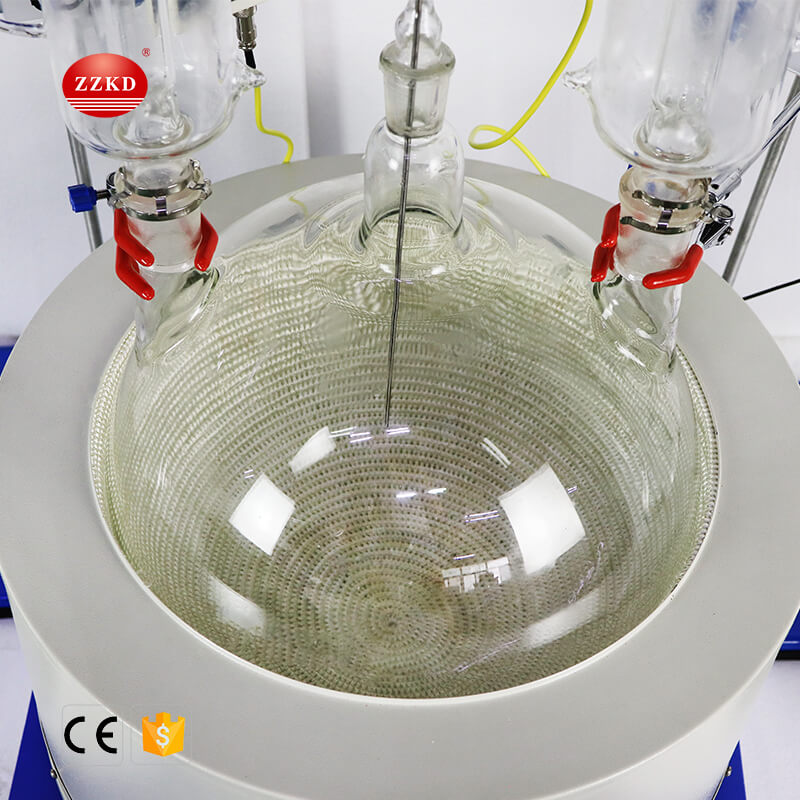

2l Quick Path Distillation Equipment

Conventional distillation processes usually require much larger equipment to realize the necessary stage of purity required for a selected utility. At the same time, short-path distillation tools can obtain as much as 99% distillate purity using multiple parts in a small workspace. Short-path distillation is a straightforward method that entails the distillate touring a brief distance. This technique is used in many kinds of distillation. This distillation is completed beneath strain which decreases the boiling point of the liquid.Short path distillation equipment for sale.

Short-path distillation tools is often used with low temperature pump and vacuum pumps to increase the effectivity of the whole short-path distillation system. The benefit of this method is that the heating temperature might be tremendously decreased at its reduced pressure. Evaporation occurs mechanically when the pressure is decreased. Then condense it, you don't have to spend a lot, simply add slightly stress, otherwise the distillate will condense at regular standard temperature. Therefore, there is not any reason to keep the distillate in a condensed state for a very long time.

Short path distillation package is a process or approach in which the distillate factor travels a small distance and is distilled, travels a couple of centimeters, and is accomplished under decreased pressure. If you need a traditional example, mention that distillation involves distilling from a glass bulb to a different bulb. Traditional distillation strategies have been unable to satisfy the needs of the market, and this type of course of usually follows the extraction technique as the final high quality assurance system for green merchandise.

For better product refinement, the method can run the fabric through greater than as quickly as. The whole working strategy of fractional distillation starts with heating the feed material so that the material evaporates. On prime of the feed material flask it's linked with a fractionating column, which cooling agent will around the column and offers the cooling impact on the inner column surface. As the vapor will get in touch with the column, the upper boiling level supplies condense back into liquid type the place the low boiling level materials are going to keep evaporating upwards. As the vapor travels along the column, it the excessive boiling level substances shall be condensed and falling downward, again into the originate. The low boiling level substance will evaporate and flow into the condenser that branched out at the high for collection function.

Quick Path Distillation Equipment On The Market

Distillation is one of the most necessary thermal separation strategies. The short-path distillation package is a compact purification technique that's best for laboratory functions that require a minimum instrument footprint. This low stress technique uses a quantity of flasks and a shorter extraction feed to separate the condensing medium from a quantity of centimeters of path.

The short-path distillation is equipped with a inside condenser which is reverse to the heating floor, and make the operation pressure reduce to beneath zero.001mbar. Its relative low boiling temperature could be very appropriate for the material with warmth sensitive and excessive boiling point. Fractional distillation is one other type of distillation approach that broadly used for botanical extraction refinement, particularly for hashish. The feed materials goes to be separated into totally different part elements. The basic principle for fractional distillation is similar to that of quick path distillation which is to utilize the variations of boiling points of parts to evaporate and condense them individually. Short-path distillation is a distillation approach where the distillate travels a brief distance.

The evaporation price will increase with the rise of temperature, however the separation issue sometimes decreases with the rise of temperature. Therefore, the thermal stability of the processed material should be taken as the premise, and a more economical and reasonable distillation temperature must be chosen. Short path distillation equipment has 2L 5L kind, suitable for home distillation and laboratory analysis.

Some short path vacuum distillation equipment relies on mechanical means to create a film for efficient evaporation. For instance, a rotary evaporator makes use of a rotating spherical backside flask to create a film on the glass walls. A falling film evaporator performs an analogous function that makes use of gravity to create an evaporative movie that runs down the heated column. There are two main distillation processes within the CBD industry that are generally recognized in the market as short path distillation and wiped film distillation.Short path distillation cannabinoids.

The short-path distillation is equipped with a inside condenser which is reverse to the heating floor, and make the operation pressure reduce to beneath zero.001mbar. Its relative low boiling temperature could be very appropriate for the material with warmth sensitive and excessive boiling point. Fractional distillation is one other type of distillation approach that broadly used for botanical extraction refinement, particularly for hashish. The feed materials goes to be separated into totally different part elements. The basic principle for fractional distillation is similar to that of quick path distillation which is to utilize the variations of boiling points of parts to evaporate and condense them individually. Short-path distillation is a distillation approach where the distillate travels a brief distance.

How To Do Brief Path Distillation?

It is principally used for enrichment, crystallization, drying, separation, drug, solvent recycling, bio-pharmaceutical business. Under vacuum situations, it is heated at a constant velocity to form a large-area thin movie on the cylinder wall to extend the evaporation efficiency. The basic principle behind distillation is separation of parts by completely different boiling factors. It begins with the conversion of the feed materials into a vapor and then condense it into liquid form under controlled temperature and stress when it passes through the condenser column. Vapor will condense back into liquid form within the condenser column and be guided to a collector flask and subsequently finishes a simple distillation process.

With the legalization of cbd oil in more & more nations, this small brief path distillation equipment is popular used in cbd distillation, clove oil, essential oil, etc. The brief path distillation caneffectively cut back material waste.The liquid is simply need to journey a short distance by adopting brief path distillation. Hence much less compound is lost through the distillation course of. High effectivity to make the distillation with a steadier setup and stainless steel chilly entice. This is a superb option to process distillation in a lab.

During the short-path course of, a boiling flask is used to warmth crude oil and the oil is agitated with a magnetic stirrer. The compounds are separated within the oil utilizing warmth till they transform into vapor. The vaporized compounds stand up and then are chilled again to a liquid utilizing a condensing coil. Spinning band is constructed upon the bottom of simple fractional distillation with additional improved processing efficiency.

Short-path distillation separates components from the extracted oil by capitalizing on the differing chemical traits of the constituent compounds. The solubility and vapor strain of compounds in a mixture have an effect on the evaporation step during distillation.