Making Distillate with Rotovap

The rotovap, short for rotary evaporator, is a crucial piece of equipment in the world of distillation. It is widely used in various industries, including chemistry, pharmaceuticals, and essential oil extraction. In this article, we will explore the process of making distillate with a rotovap, step by step. Whether you are a seasoned professional or just starting, understanding this essential tool and its operation is vital for achieving high-quality distillates.

Before diving into the distillation process, let's get acquainted with the rotovap for sale itself.

Subheading 1: What is a Rotovap?

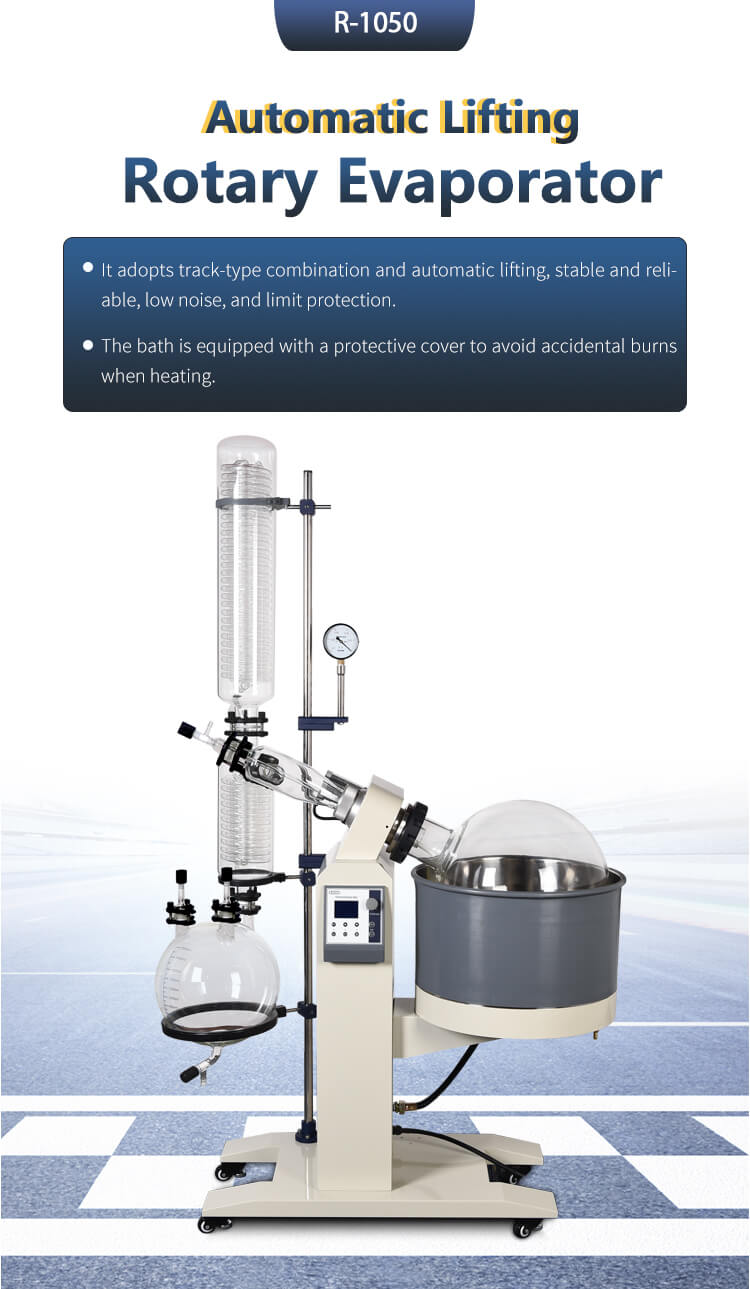

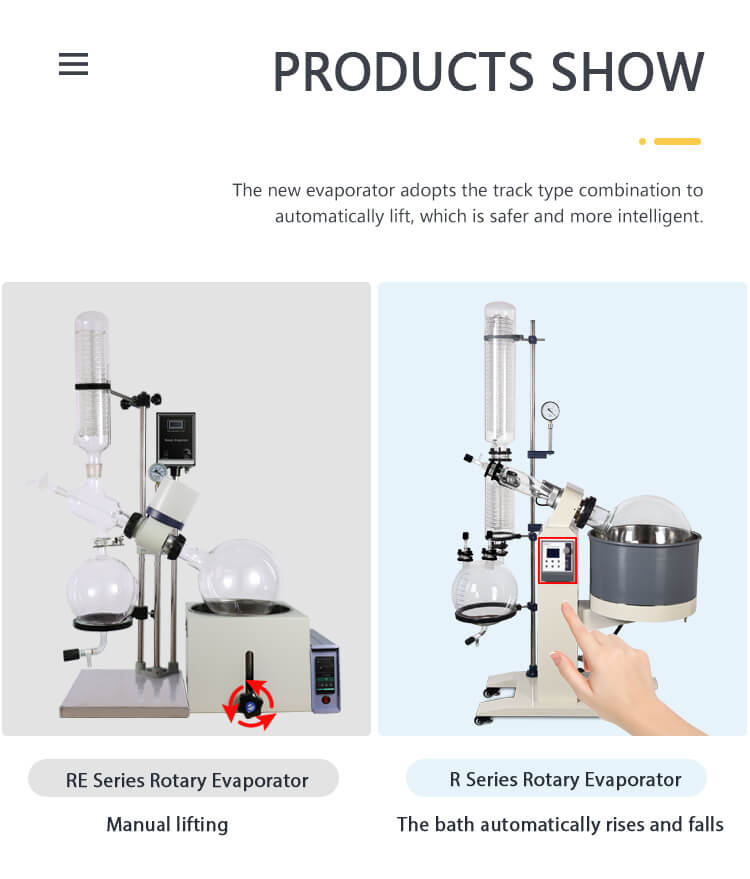

A rotovap is a specialized laboratory equipment designed for the efficient and gentle removal of solvents from samples. It consists of a rotating flask, a heating bath, a condenser, and a vacuum pump. The combination of these components allows for precise control over temperature and pressure, making it ideal for distillation purposes.

Subheading 2: Setting Up the Rotovap

Before you start distillation, it's crucial to set up your rotovap correctly.

Setting Up Your Rotovap

1. Assembling the Components: Begin by assembling the main components of the rotovap. Connect the flask to the condenser and attach the vacuum pump.

2. Secure the Flask: Ensure the flask is securely attached to the rotary evaporator, and the sealing is airtight.

3. Prepare the Sample: Place your sample in the flask, ensuring it's appropriate for the distillation process.

Subheading 3: The Distillation Process

Now that your rotovap is set up, it's time to proceed with the distillation process.

The Distillation Process

1. Heating the Bath: Start by heating the bath to the desired temperature. This temperature will vary depending on the properties of the sample and the compounds you want to distill.

2. Applying Vacuum: Turn on the vacuum pump to create a low-pressure environment within the system. This lowers the boiling point of the solvent, allowing it to evaporate more efficiently.

3. Rotating the Flask: Initiate the rotation of the flask. The rotating motion helps in even distribution of heat and ensures efficient solvent evaporation.

Subheading 4: Collecting the Distillate

As the distillation process proceeds, it's essential to collect the distillate properly.

Collecting the Distillate

1. Condensation: The vaporized solvent travels through the condenser, where it is cooled and condensed back into a liquid form.

2. Collection Flask: The condensed distillate is collected in a separate flask. This is where you obtain your purified distillate.

3. Monitoring the Process: Keep a close eye on the process, adjusting temperature and vacuum levels as needed to achieve the desired results.

Subheading 5: Analyzing and Storing the Distillate

Once you've collected your distillate, it's important to analyze and store it correctly.

Analyzing and Storing the Distillate

1. Quality Control: Analyze the purity and composition of your distillate using appropriate analytical techniques to ensure it meets your specifications.

2. Storage: Store the distillate in suitable containers and conditions to maintain its quality over time.

In conclusion, making distillate with a rotovap is a precise and efficient process that requires careful setup and monitoring. Whether you're in the pharmaceutical, chemical, or essential oil industry, understanding the operation of this essential equipment is essential for achieving high-quality distillates. With the right knowledge and attention to detail, you can produce distillates that meet your specific needs and standards, contributing to your success in your respective field.