Lab Emulsifying Mixer: Enhancing Laboratory Mixing and Emulsification

Laboratory processes often require precise and efficient mixing and emulsification to achieve desired results. In the pursuit of advancements in research, development, and quality control, scientists and researchers heavily rely on cutting-edge equipment. Among these essential tools is the lab emulsifying mixer, a versatile device that plays a pivotal role in various applications. In this article, we will explore the fundamental principles of a lab emulsifying mixer, its functionalities, and its diverse applications. Additionally, we will delve into an application case to showcase its practical significance.

An Insight into the Lab Emulsifying Mixer

The Lab Emulsifying Mixer, a versatile and essential piece of equipment, holds a significant role in the realm of laboratory processes. Its primary purpose is to homogenize and emulsify substances with precision and efficiency, contributing to the advancement of research, development, and quality control in various industries.

This mixer operates on the principle of combining mechanical force with high-speed rotation, which effectively breaks down liquids, solids, or immiscible components. The two most common configurations are the rotor-stator mixers and high-pressure homogenizers.

A) Rotor-Stator Mixers feature a rotating rotor and stationary stator. The rotor generates powerful suction, drawing materials into the space between the rotor and stator. Intense mechanical shearing forces disperse the materials, yielding a uniform mixture or emulsion.

B) High-Pressure Homogenizers operate differently by utilizing high-pressure pumps to force materials through narrow gaps or valves. The process subjects the substances to turbulence and shear, resulting in finely homogenized mixtures and stable emulsions.

Due to its versatility and efficiency, the lab emulsifying mixer finds diverse applications in pharmaceuticals, food and beverage, cosmetics, and chemical research, empowering researchers and scientists to achieve consistent and reliable outcomes in their experiments and productions.

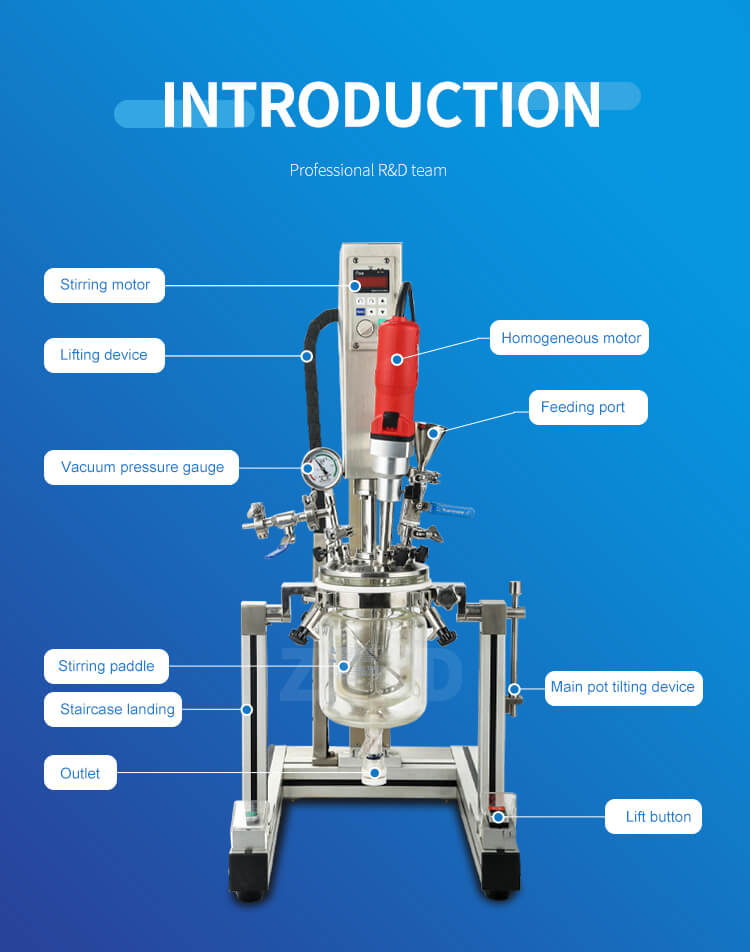

Key Components and Operating Principles

A) Rotor-Stator Mixers:

The rotor-stator mixer consists of two main components: the rotor, which rotates at high speed, and the stator, which remains stationary. When the rotor spins, it creates a powerful suction force that draws materials into the space between the rotor and the stator. Subsequently, intense mechanical shearing forces disrupt and disperse the materials, resulting in a uniform mixture or emulsion.

B) High-Pressure Homogenizers:

High-pressure homogenizers operate on a different principle. They use high-pressure pumps to force materials through narrow gaps or valves, subjecting them to intense turbulence and shear. This process efficiently breaks down particles, resulting in finely homogenized mixtures and stable emulsions.

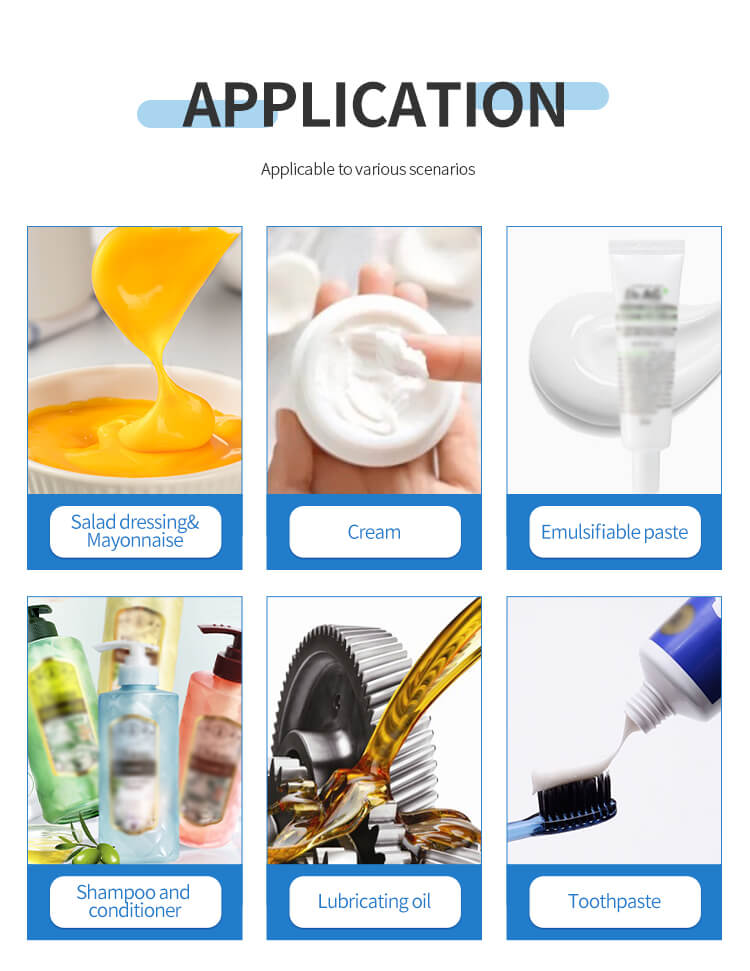

Applications of Lab Emulsifying Mixers

Lab emulsifying mixers find applications in a wide range of industries due to their versatility and effectiveness in mixing and emulsification processes. Some notable applications include:

A) Pharmaceutical Industry:

In pharmaceutical research and production, precise mixing and emulsification are crucial for drug formulation and development. Lab emulsifying mixers facilitate the production of stable pharmaceutical emulsions, suspensions, and liposomal formulations, ensuring consistent drug delivery systems.

B) Food and Beverage Industry:

In the food and beverage sector, lab emulsifying mixers are utilized to create smooth and consistent textures in products such as sauces, dressings, and beverages. They aid in the dispersion of ingredients and the prevention of phase separation, enhancing product quality and shelf life.

C) Cosmetics and Personal Care Products:

The cosmetic industry relies on lab emulsifying mixers to produce creams, lotions, and emulsions with desired textures and appearances. These mixers help achieve a smooth and evenly distributed product, ensuring an enhanced user experience.

D) Chemical Research and Production:

Chemical laboratories utilize lab emulsifying mixers for various applications, including the production of stable emulsions for testing and research purposes. Additionally, they aid in chemical reactions and catalyst dispersion.

Case : Advancing Nanoparticle Delivery Systems

In recent years, nanotechnology has revolutionized drug delivery systems, enabling targeted and controlled drug release. Nanoparticle-based drug carriers have shown great promise in improving therapeutic efficacy and reducing side effects. However, the production of these nanoparticles with uniform size and surface properties is a challenging task. Researchers at a pharmaceutical laboratory tackled this obstacle by employing a lab emulsifying mixer.

The study aimed to develop lipid-based nanoparticles for an anticancer drug delivery system. The researchers utilized a high-pressure homogenizer as their lab emulsifying mixer of choice. The process involved dispersing a lipid mixture in an aqueous phase containing the drug. The high-pressure homogenizer exerted intense shear and turbulence forces on the mixture, resulting in a finely homogenized emulsion with uniformly sized lipid nanoparticles.

The final nanoparticle formulation exhibited remarkable stability and demonstrated controlled drug release kinetics. The use of the lab emulsifying mixer facilitated the production of nanoparticles on a scalable level, which is crucial for future clinical translation. This case study exemplifies the significance of lab emulsifying mixers in advancing pharmaceutical research and personalized medicine.

Factors Influencing Mixer Performance

The performance of a lab emulsifying mixer depends on various factors that need careful consideration during experimentation and operation. Some of the key factors include:

A) Speed and Shear Rate:

The rotational speed of the rotor-stator mixer or the pressure applied in high-pressure homogenizers significantly affects the shear rate and, consequently, the emulsification or mixing efficiency. Optimizing these parameters is essential to achieve the desired results.

B) Material Properties:

The physical properties of the materials being processed, such as viscosity, surface tension, and particle size, impact the mixing and emulsification process. Understanding and adapting to these properties ensure better outcomes.

C) Equipment Design:

The design and configuration of the lab emulsifying mixer play a vital role in its performance. Factors such as the geometry of the rotor-stator assembly or the homogenization valve design in high-pressure homogenizers can affect the homogenization efficiency.

Best Practices and Safety Considerations

To achieve optimal results and ensure safety in the laboratory, researchers should adhere to best practices when using lab emulsifying mixers. Some important guidelines include:

A) Proper Calibration and Setup:

Calibrate the mixer regularly and set up the equipment according to the manufacturer's guidelines to ensure accurate and consistent results.

B) Batch Size and Sample Volume:

Consider the appropriate batch size and sample volume that the mixer can handle effectively to prevent overloading or underutilization.

C) Cleaning and Maintenance:

Thoroughly clean the mixer after each use to prevent cross-contamination and maintain its efficiency. Regular maintenance and inspection help prolong the equipment's lifespan.

D) Personal Protective Equipment (PPE):

Always wear appropriate PPE, such as lab coats, gloves, and safety goggles, when operating the mixer to protect against potential splashes or spills.

E) Ventilation and Environmental Control:

Ensure the laboratory has proper ventilation and environmental controls to manage any fumes, aerosols, or potential hazards generated during the mixing process.

Conclusion

The lab emulsifying mixer is a crucial tool in laboratories across various industries. Its ability to homogenize and emulsify materials efficiently enables advancements in pharmaceuticals, food and beverage products, cosmetics, and chemical research. With the proper understanding of its operating principles, optimization of key factors, and adherence to best practices, researchers can harness the full potential of lab emulsifying mixers, driving innovation and scientific progress to new heights. As technology continues to evolve, these mixers will undoubtedly remain indispensable assets in the pursuit of excellence in laboratory processes.