Isopropyl Alcohol Short Path Distillation: An In-Depth Guide

Short path distillation is a specialized technique used in the purification and separation of various substances, and when applied to isopropyl alcohol, it showcases remarkable efficiency. This process involves the distillation of liquid material at a reduced pressure, which decreases the boiling point and aids in the separation of compounds with minimal thermal decomposition.

In this context, isopropyl alcohol short path ditilation unit is a critical method, especially in industries where high-purity alcohol is a necessity. This process ensures that the end product is of superior quality, devoid of impurities that might affect its intended use.

The Process of Short Path Distillation

Understanding the process of isopropyl alcohol short path distillation involves recognizing its various stages. Initially, the isopropyl alcohol is heated in a flask, and as it evaporates, the vapor travels a short distance before condensing. This short travel distance is crucial, as it prevents the decomposition of heat-sensitive compounds.

The key here is the reduced pressure environment within the distillation apparatus. This pressure reduction lowers the boiling point of the alcohol, enabling the distillation process to occur at temperatures that are much more manageable and less damaging to the isopropyl alcohol.

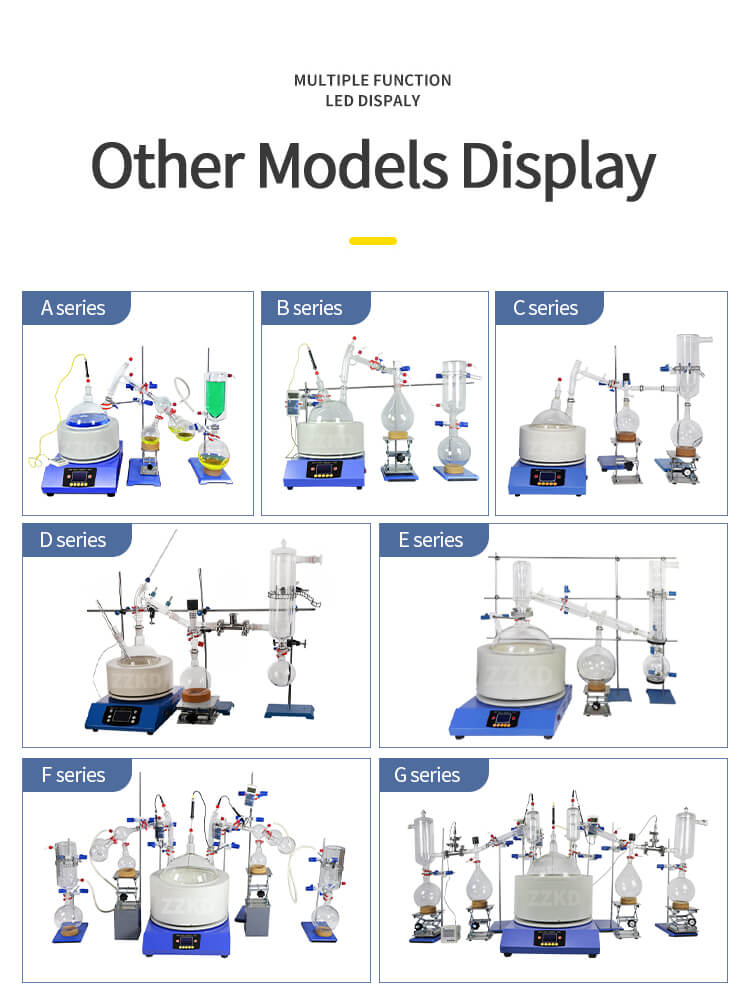

Equipment Used in Short Path Distillation

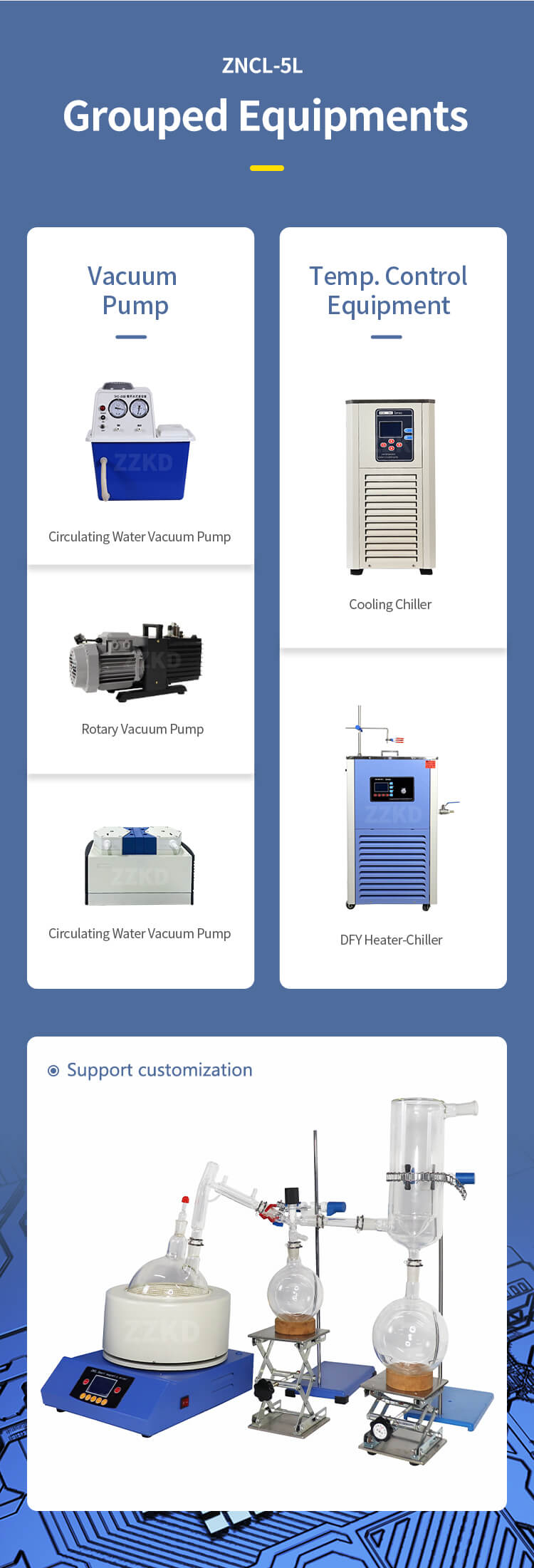

The equipment used in the isopropyl alcohol short path distillation process plays a significant role in its efficiency. Typically, this includes a heated flask for evaporation, a cooling system for condensation, and a vacuum pump to create the necessary reduced pressure environment.

Quality equipment, such as that provided by ZZKD Machinery and Instrument Equipment Co., Ltd., ensures a consistent and reliable distillation process. Their state-of-the-art distillation units are designed to handle the sensitive nature of isopropyl alcohol, ensuring purity and quality in the final product.

The Role of Reduced Pressure

Reduced pressure is a cornerstone of the isopropyl alcohol short path distillation process. By lowering the atmospheric pressure within the distillation setup, the boiling point of the alcohol is significantly reduced. This not only speeds up the process but also minimizes the risk of thermal degradation.

The vacuum systems used to achieve this reduced pressure are sophisticated and require careful calibration. The ability to maintain a stable and appropriate level of reduced pressure is crucial for the success of the distillation process.

Applications of Purified Isopropyl Alcohol

Once purified through short path distillation, isopropyl alcohol finds extensive use in various industries. Its applications range from being a solvent in the pharmaceutical industry to a cleaning agent in electronic manufacturing. The purity of the alcohol is critical in these applications, as even minor impurities can have significant consequences.

The demand for high-purity isopropyl alcohol is continuously growing, making efficient and reliable distillation methods like short path distillation invaluable.

Conclusion and Call to Action

Isopropyl alcohol short path distillation represents a pinnacle of modern distillation techniques, combining efficiency with precision. For businesses and industries looking to procure high-quality distillation equipment, ZZKD Machinery and Instrument Equipment Co., Ltd. offers an array of top-notch options. Their expertise in the field ensures that clients receive equipment that is not only effective but also tailored to meet specific distillation needs.

For more information on their products and services, or to explore how they can assist in your isopropyl alcohol distillation needs, visit ZZKD Machinery. Engaging with their team can open doors to enhanced productivity and quality in your distillation processes.