How to Make Strawberry Protein Powder with a Spray Dryer?

Introduction to Strawberry Protein Powder

Strawberry protein powder is a nutritious and delicious supplement that masterfully combines the sweet and refreshing essence of strawberries with the substantial health benefits of protein. This fusion creates a product that is not only beneficial for muscle growth and recovery but also enjoyable to consume, making it a popular choice among a wide range of individuals, from athletes to health-conscious consumers.

At its core, strawberry protein powder typically consists of a high-quality protein base such as whey, soy, pea, or rice protein, catering to various dietary needs and preferences. The choice of protein is crucial as it determines the powder's suitability for different diets, such as vegetarian, vegan, or lactose-intolerant. To this protein base, strawberry flavoring – either in the form of natural strawberry extract or artificial flavors – is added to provide a palatable and aromatic strawberry taste. This flavoring is essential in masking the sometimes bland or unappealing taste of plain protein powders, making the supplement more appealing to a broader audience.

This guide explores how to make strawberry protein powder using a spray dryer, a method known for its efficiency and quality results. You'll learn about the benefits of strawberry flavor and the essential components of creating a protein powder that's not only nutritious but also delicious.

High-Efficiency Spray Dryer - Model LPG-2L

Suitable for a wide range of drying applications, from pharmaceuticals to food technology.

Function: Rapid drying with precise temperature control for sensitive materials.

Water Evaporation Capacity: Adjustable from 0 to 2000ml/h to suit various scales of operation.

Temperature Control: Inlet air temperature up to 300°C and outlet temperature up to 140°C, with real-time control error of ±1°C for optimal drying conditions.

Size and Interface: Compact dimensions at 650×500×1500mm, with a user-friendly 7-inch LCD touch operation display for ease of use and monitoring.

Overview of Spray Drying Technology

Spray drying technology is a pivotal process in modern powder production, particularly in the creation of high-quality protein powders like strawberry protein powder. This method is renowned for its efficiency, consistency, and ability to preserve the integrity of complex ingredients.

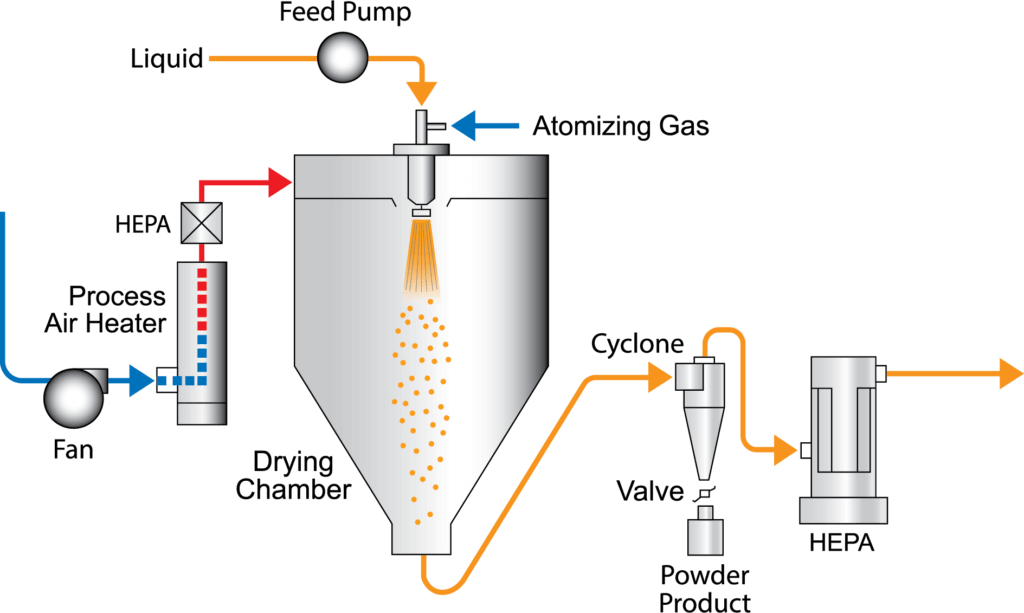

At its most basic, spray drying involves converting a liquid mixture into a dry powder form. This is achieved through a process where the liquid (in this case, a mixture of protein and strawberry flavor) is atomized into a fine spray of droplets. These droplets are then introduced into a drying chamber with hot air. As the droplets come into contact with the hot air, the moisture rapidly evaporates, leaving behind solid particles – the powder. The key to this process is the speed at which drying occurs, which helps preserve the nutritional and sensory qualities of the original mixture.

There are several reasons why spray drying is particularly beneficial for making protein powders:

1. Consistency and Control: Spray drying allows for precise control over particle size, moisture content, and density. This level of control is crucial for the consistency and solubility of protein powders, impacting how well the powder dissolves in liquids.

2. Flavor and Nutrient Preservation: The rapid drying process helps preserve the flavor and nutritional value of the ingredients. This is particularly important for strawberry protein powder, as it ensures that the final product retains the delightful taste and beneficial properties of strawberries and the protein source.

3. Scalability: Spray drying is highly scalable, making it suitable for large-scale production without sacrificing quality. This is essential for commercial production of protein powders.

4. Shelf Stability: The resulting powder is low in moisture, which enhances its shelf life. This is crucial for protein powders, as it ensures they remain effective and safe for consumption over an extended period.

5. Versatility: This technology can be adapted to different ingredients and formulations, allowing for the creation of a wide range of protein powders, including various flavors and protein sources (like whey, soy, pea).

Spray drying technology is essential for anyone looking to produce high-quality strawberry protein powder. Its ability to efficiently convert liquid mixtures into stable, soluble, and uniform powders makes it the preferred choice in the industry. By understanding and leveraging this technology, manufacturers can produce protein powders that are not only nutritious and effective but also enjoyable for consumers, featuring the full, rich flavor of strawberries combined with the benefits of protein.

Compact Spray Dryer - Model LPG-5L

Ideal for small scale production and research.

Function: Efficient moisture evaporation for heat-sensitive products.

Inlet Temperature: 140-350°C allows for versatile processing options.

Moisture Evaporation Capacity: 5 kg/h for moderate drying needs.

Dimensions: 1.8×0.93×2.2 m, compact design for limited spaces.

Process of Spray Drying Strawberries

The process of spray drying a strawberry mixture to create a high-quality strawberry protein powder involves several critical steps and careful monitoring of parameters to ensure optimal results. Here's a detailed overview of the process:

1. Preparation of Strawberry Mixture:

Ingredient Mixing: The process begins by creating a homogeneous mixture of strawberry essence or extract and a protein base (like whey, soy, pea, or rice protein). Additional ingredients, such as sweeteners, stabilizers, or preservatives, may be added to enhance flavor, texture, and shelf life.

Solution Consistency: The mixture must have the right consistency, which is crucial for efficient spray drying. It should be a liquid that can be easily atomized. If necessary, the mixture is diluted or thickened to achieve the desired viscosity.

2. Atomization of the Mixture:

Spray Nozzles: The mixture is fed into the spray dryer through nozzles that atomize the liquid into fine droplets. The size of these droplets is critical, as it affects the drying speed and the quality of the final powder.

Nozzle Selection: Different types of nozzles (like rotary, two-fluid, pressure nozzles) can be used depending on the desired droplet size and the properties of the mixture.

3. Drying Chamber:

Introduction to Hot Air: In the drying chamber, the atomized droplets come into contact with hot air, leading to rapid evaporation of moisture.

Temperature Control: The air temperature is a crucial parameter. It must be high enough to evaporate moisture quickly but not so high as to degrade the nutrients or flavor of the strawberry mixture. Typically, inlet temperatures can range from 150°C to 200°C, while outlet temperatures are lower.

4. Monitoring and Adjusting Parameters:

Moisture Content: Continuously monitor the moisture content of the powder. The goal is to achieve a low moisture content without over-drying.

Air Flow and Heat: Adjusting the air flow and heat within the dryer can help control the drying rate and temperature.

Residence Time: The time the particles spend in the drying chamber should be optimized to ensure they are dried adequately but not excessively.

5. Collection of Powder:

Separation: The dried particles are separated from the air using a cyclone separator or bag filters.

Quality Check: The powder is checked for consistency, particle size, moisture content, and flavor profile.

6. Post-Processing Steps:

Sieving: The powder may be sieved to ensure uniform particle size.

Additional Flavoring: Additional flavoring or nutrients can be blended into the powder after drying, if needed.

7. Packaging:

Protection from Moisture and Air: The powder is packaged in airtight containers to protect it from moisture and air, preserving its quality and shelf life.

By meticulously controlling these aspects of the spray drying process, manufacturers can produce high-quality strawberry protein powder with excellent flavor, nutritional value, and solubility, meeting the demands of health-conscious consumers.

Mid-Size Spray Dryer - Model LPG-10L

Suitable for moderate production in industrial and academic settings.

Function: Balanced performance for consistent particle size distribution.

Inlet Temperature: 140-350°C for a wide range of materials.

Moisture Evaporation Capacity: 10 kg/h, doubling the capacity of LPG-5.

Electric Heating Power: 20 kW for efficient drying processes.

Nutritional Analysis of Strawberry Protein Powder

Strawberry protein powder is not only a flavorful addition to a diet but also a rich source of various nutrients. A comprehensive nutritional analysis reveals its value in terms of protein content, vitamins, minerals, and other health benefits.

1. Protein Content:

High-Quality Protein: Strawberry protein powder typically contains a significant amount of high-quality protein, essential for muscle repair, growth, and overall body maintenance. The exact amount can vary based on the protein base used (whey, soy, pea, etc.), but it generally ranges from 15 to 30 grams per serving.

Amino Acid Profile: Depending on the protein source, the powder can include a complete profile of essential amino acids, vital for various bodily functions.

2. Vitamins:

Vitamin C: Strawberries are naturally high in Vitamin C, an antioxidant that boosts the immune system, aids in skin health, and enhances iron absorption.

Other Vitamins: Depending on the formulation, the powder may also contain other vitamins such as Vitamin A, some B vitamins, and Vitamin E, either naturally from the strawberry content or added during manufacturing.

3. Minerals:

Calcium and Potassium: Strawberry protein powders can be a good source of minerals like calcium and potassium, contributing to bone health and proper muscle function.

Trace Minerals: Other minerals such as magnesium, zinc, and iron might also be present, either naturally or as added nutrients.

4. Fiber:

Dietary Fiber: If the powder includes whole strawberry powder or other fibrous ingredients, it can be a source of dietary fiber, beneficial for digestive health.

5. Antioxidants:

Rich in Antioxidants: Strawberries are known for their antioxidant properties, primarily due to the presence of Vitamin C and other compounds like flavonoids, which help combat oxidative stress in the body.

6. Low in Fat and Carbohydrates:

Low-Calorie Option: Most strawberry protein powders are low in fat and carbohydrates, making them an ideal choice for weight management diets.

Strawberry protein powder is not just a flavorful supplement but also a nutritious option offering a wide range of health benefits. Its composition can vary depending on the brand and formulation, but generally, it provides a rich blend of proteins, vitamins, minerals, and antioxidants, making it a valuable addition to a balanced diet.

DIY Strawberry Protein Powder at Home

Making strawberry protein powder at home can be a rewarding DIY project. It's a great way to create a personalized, natural supplement. Here's a simplified method to make your own strawberry protein powder, including the necessary tools and ingredients.

Ingredients:

1. Protein Base: Choose a high-quality protein base such as whey protein isolate, soy protein, pea protein, or any other preferred protein powder. This will be the primary source of protein in your mixture.

2. Freeze-Dried Strawberries: Opt for freeze-dried strawberries as they have low moisture content and intense flavor. These can be ground into a fine powder.

3. Natural Sweeteners (Optional): Depending on your taste preference, you might want to add a natural sweetener like stevia or monk fruit.

4. Optional Additives: For extra nutrition, consider adding ground flaxseed, chia seeds, or a fiber supplement.

Tools:

1. Food Processor or High-Powered Blender: To grind the freeze-dried strawberries and mix the ingredients thoroughly.

2. Fine-Mesh Sieve or Sifter: To ensure a smooth, uniform powder.

3. Airtight Container: For storing the final product.

4. Measuring Tools: Cups and spoons for accurate ingredient portions.

Method:

1. Grind the Strawberries: Place the freeze-dried strawberries in your food processor or blender. Grind them into a fine powder. Use the sieve to remove any larger pieces.

2. Mix the Protein Base and Strawberry Powder: Combine the ground strawberry powder with your chosen protein base in the blender. Blend until well mixed. Ensure even distribution of strawberry powder throughout the protein base.

3. Add Sweeteners and Optional Additives: If using sweeteners or additional nutritional supplements, add them now and blend again until everything is mixed evenly.

4. Taste Test: Sample your powder and adjust the sweetness or strawberry flavor as needed.

5. Storage: Transfer the finished strawberry protein powder into an airtight container. Store it in a cool, dry place.

Making strawberry protein powder at home allows for customization in flavor and ingredients, ensuring you have a product that suits your dietary needs and taste preferences. While this homemade version may not have the same shelf life or consistency as commercial powders, it's a natural and satisfying way to supplement your diet with protein and the delightful flavor of strawberries.

Commercial Production of Strawberry Protein Powder

Scaling up from a home setup to commercial production of strawberry protein powder involves significant changes in process management, quality control, and adherence to regulatory standards. Here's an overview of key factors to consider for successful commercial production:

1. Industrial Equipment and Technology:

Large-Scale Spray Dryers: Commercial production requires industrial spray dryers price capable of handling large volumes of liquid efficiently.

High-Capacity Blenders: Industrial blenders are needed for mixing large batches of ingredients uniformly.

Automated Packaging Systems: For efficiency and consistency in packaging.

2. Sourcing High-Quality Ingredients:

Bulk Procurement: Source high-quality protein bases and freeze-dried strawberry powder in bulk from reliable suppliers.

Ingredient Testing: Regular testing of raw materials for quality and safety.

3. Process Optimization:

Scaling Recipes: Adjusting the formulation for large-scale production while maintaining consistency in flavor and nutritional value.

Efficiency Improvements: Streamlining the process for maximum yield and minimum waste.

Continuous Monitoring: Implementing systems for real-time monitoring of production parameters.

4. Quality Control and Assurance:

Establishing Protocols: Developing strict quality control protocols to ensure each batch meets predetermined standards.

Lab Testing: Regular laboratory testing for nutritional content, contaminants, and shelf life.

Consistency Checks: Routine checks for consistency in taste, texture, and solubility.

5. Regulatory Compliance:

Food Safety Standards: Adhering to local and international food safety standards like FDA (U.S. Food and Drug Administration) regulations.

Labeling Requirements: Ensuring accurate and compliant labeling, including nutritional information, ingredient list, and allergen statements.

Certifications: Obtaining necessary certifications (e.g., organic, non-GMO, GMP - Good Manufacturing Practices).

6. Packaging and Storage:

Moisture-Proof Packaging: Using packaging materials that protect the powder from moisture and air.

Shelf Life Optimization: Packaging methods that extend shelf life, such as nitrogen flushing.

Storage Conditions: Establishing optimal storage conditions to preserve freshness and prevent degradation.

7. Market Analysis and Compliance:

Consumer Research: Understanding market demands and consumer preferences.

Competitive Analysis: Staying competitive in terms of pricing, quality, and product offerings.

Marketing and Distribution: Developing effective marketing strategies and distribution channels.

8. Environmental and Ethical Considerations:

Sustainable Sourcing: Prioritizing sustainability in ingredient sourcing.

Waste Management: Implementing environmentally friendly waste management practices.

Ethical Practices: Ensuring fair labor practices throughout the supply chain.

Scaling up to commercial production of strawberry protein powder is a complex process that requires careful planning, significant investment in technology and equipment, stringent quality control, and rigorous adherence to regulatory standards. By focusing on these key areas, manufacturers can produce a high-quality product that meets the demands of the market while adhering to safety, ethical, and environmental standards.

Conclusion

Journey of creating strawberry protein powder is a complex fusion of science, culinary expertise, and strategic marketing. Starting with the careful selection of high-quality, preferably organic strawberries, each step in the process is crucial to the final product's success. The use of spray drying technology exemplifies the intricate balance between preserving the delicate natural flavors and nutrients of strawberries while ensuring the powder's shelf stability and ease of use. The choice of protein source, whether whey, soy, or pea, further influences the nutritional profile and appeal of the product to different consumer segments.

As consumer preferences evolve, the market for strawberry protein powder continues to grow, driven by trends towards health-conscious, convenient, and versatile dietary options. This product not only caters to those seeking a nutritious supplement but also appeals to the gourmet, offering a delightful and healthy twist to various recipes.

In the ever-evolving landscape of food and nutrition, strawberry protein powder stands out as a prime example of how traditional ingredients can be transformed through technology and innovation to meet modern dietary needs and preferences.

FAQs:

1. Benefits of Using a Spray Dryer for Making Protein Powder:

Consistency: Spray drying helps achieve a uniform particle size, which is crucial for consistent quality.

Solubility: This method enhances the solubility of protein powders, making them easier to mix with liquids.

Preservation of Nutrients: Spray drying is relatively quick and often operates at lower temperatures, which can help in preserving the nutritional value of the protein.

Scalability: It's a method suitable for large-scale production, offering efficiency in terms of time and cost.

Shelf Stability: Spray-dried powders generally have a longer shelf life, due to reduced moisture content.

2. Making Strawberry Protein Powder at Home without Professional Equipment:

You can create a basic version of strawberry protein powder at home by dehydrating strawberries (either using a dehydrator or a conventional oven at a low temperature) and then grinding them into a powder.

Mix this strawberry powder with a purchased protein powder base (like whey, pea, or rice protein) to create your own blend.

Note that the texture and solubility might not be as refined as commercially produced powders.

3. Ensuring Nutritional Value in Homemade Strawberry Protein Powder:

Use Fresh Ingredients: Start with fresh, ripe strawberries for the best nutritional content.

Gentle Drying Process: Use a low-temperature drying process to preserve vitamins and antioxidants.

Proper Storage: Store your powder in a cool, dry place to preserve its nutritional qualities.

Consider Adding Supplements: You might want to add additional supplements to enhance the nutritional profile, like vitamin C or fiber.

4. Creative Ways to Use Strawberry Protein Powder in Recipes:

Smoothies: Blend it into smoothies for a fruity protein boost.

Baking: Use it in pancakes, muffins, or protein bars for a healthy twist.

Oatmeal or Yogurt: Stir it into oatmeal or yogurt for a flavorful and nutritious addition.

Homemade Protein Shakes: Combine it with milk or a milk alternative, add a banana or other fruits, and blend for a quick protein shake.

5. Marketing Homemade Strawberry Protein Powder:

Highlight Unique Qualities: Emphasize the homemade aspect, natural ingredients, and any unique features of your product.

Use Social Media: Platforms like Instagram and Pinterest are great for showcasing your product through attractive images and recipes.

Engage with Local Communities: Attend farmers' markets or local events to introduce your product to the community.

Offer Samples: Letting people taste your product can be a powerful marketing tool.

6. Future Trends in Protein Powder Production and Flavor Innovation:

Plant-based Proteins: There’s a growing trend towards plant-based and vegan protein powders.

Sustainable Sourcing: Consumers are increasingly interested in sustainably sourced ingredients.

Exotic Flavors: Apart from classic flavors like chocolate and vanilla, exotic and unique flavors are becoming popular.

Functional Additives: Adding supplements like probiotics, vitamins, or minerals to enhance health benefits is becoming more common.

Personalization: Customized protein powders based on individual dietary needs and preferences might become more prevalent.