How To Extraction Of Lemongrass Oil By Steam Distillation?

Among many health care products, essential oils not only smell fragrant, but also have the functions of sterilization and delicate skin. With the continuous discovery of their new uses, the long-term demand for essential oils is guaranteed.

This blog will introduce the best way of essential oil extraction including process, equipment and benefits to meet the market demand for essential oil extraction.

Main equipment used for this blog:closed loop extractor kit, essential oil extraction machine, supercritical extraction machine. Auxiliary equipment used: circulating water vacuum pump, low temperature coolant circulating pump.

What Are Essential Oils(Lemongrass Oil Extraction)?

Essential oils are extracted from leaves, flowers, seeds, fruits, roots, barks, resins, wood hearts and other parts of plants by steam distillation, cold pressing, liposuction and solvent extraction. volatile substances. In addition to extracting essential oils from a certain part of the plant, some plants can extract essential oils from several parts. For example, bitter orange can extract essential oils from three parts: buds, leaves and fruits.

However, not all plants can produce essential oils, only those with balsam glands can produce essential oils. The distribution of balsam glands is different in different plants, and some are on petals, leaves, rhizomes or tree trunks. After the sachet is refined and extracted, it becomes what we call "plant essential oil".

Lemongrass Oil Extraction Process

Various industrial fields have different requirements for lemongrass oil parameters, which has promoted the development of essential oil extraction machines. The following is the essential oil extraction process:

1.Solvent Extraction

Its process is complicated, and the output of the extracted essential oil is relatively small. Solvent extraction is mostly used for the extraction of delicate and fragile plant petals or resins that do not like heat sources.

First, the volatile and non-volatile essence components of the crushed plants are extracted with a solvent of carbohydrates such as petroleum or benzene; then the extracted mixture is filtered again with a solvent, and after the solvent is volatilized, a compound containing The semi-solid waxy substance of alcohol component; finally, the essential oil is selectively extracted from the waxy substance with alcohol to obtain high-quality, high-concentration plant essential oil. Therefore, the same plant parts, the essential oils obtained by solvent extraction will have different components, and of course their prices will also be different.

The flowers, petals, flower buds and other parts of plants are extracted by solvent extraction. The product after the first extraction is called "Concrete". If the natural secretions of plants, such as gums, resins or sap are extracted, the first product is called "resinoid". After the first product "resin" or "congealed fat" is extracted again with alcohol or alcohol, the second-stage final product obtained is called Absolute Oil. Finally, the oil in the balsam is washed away with volatile pure alcohol to obtain a delicate and expensive absolute oil.

2.Extrusion Method

The vast majority of citrus essential oils, such as sweet orange, bergamot, grapefruit, and orange, are extracted this way, because most citrus essential oils cannot resist the heat of distillation and will destroy it during the extraction process. of the essence. However, Lime, which is also a citrus, is extracted by distillation, because the aroma of Lime essential oil extracted by distillation is more unique, and the quality is better than that extracted by extrusion.

Until the 1930s, squeezing was performed manually by humans, by rubbing the peel back and forth vigorously while holding a piece of natural sponge. The peel is rubbed and squeezed to exude juice, and the essential oils exuded from the peel are then completely absorbed by the natural sponge, and then the workers squeeze the plump and soaked sponge to squeeze the essential oils into the collection bottle. These squashed sponges can then be sold as scented sponges.

Today, most essential oil manufacturers have replaced manual work with machines in consideration of cost and output, but there are still people in Grasse in southern France extracting citrus essential oils by hand, and they can still be bought in the small streets of Provence. to a natural fragrant sponge.

3.Supercritical Extraction

Use specific equipment to make carbon dioxide reach a supercritical state (temperature above 32 °C and pressure above 7.2 MPa), extract the essential oil in the material, and then separate the essential oil through changing temperature and pressure. Therefore, supercritical extraction consists of two processes: extraction and separation.

4.Subcritical Extraction

Sub-critical fluid extraction technology uses sub-critical fluid as an extraction agent in a closed, oxygen-free environment. In the low-pressure pressure vessel, according to the principle of similar compatibility of organic substances, through the molecular diffusion process of the extraction material and the extraction agent during the soaking process, the fat-soluble components in the solid material are transferred to the liquid extraction agent, and then evaporated under reduced pressure. The process separates the extractant from the target product, and finally obtains the target product.

From the perspective of the essential oil extraction industry, the higher the fineness of the finished product processed by the essential oil extraction plant, the higher the economic value. Therefore, the choice of extraction process is the key. How to choose the best essential oil extractor?

Recommended 3 Types of Essential Oil Extractors

Different essential oil extractors have different application specifications. Customers can freely choose the best essential oil extraction machine according to the processing method and output of essential oil products.

| Equipment | closed loop extraction | Essential Oil Extractor | Supercritical Extractor |

| Volume | 1Lb-80Lb | 10L-3000L | 10L-25L |

| Power | - | 3kw-150kw | - |

| Size | Small | Small-Big | Big |

| Recommended | ★★ | ★★★ | ★★★ |

Lemongrass Oil Extractor You Care About

ZZKD will introduce 3 kinds of essential oil extraction machines in detail according to the essential oil extraction process and combined with years of experience.

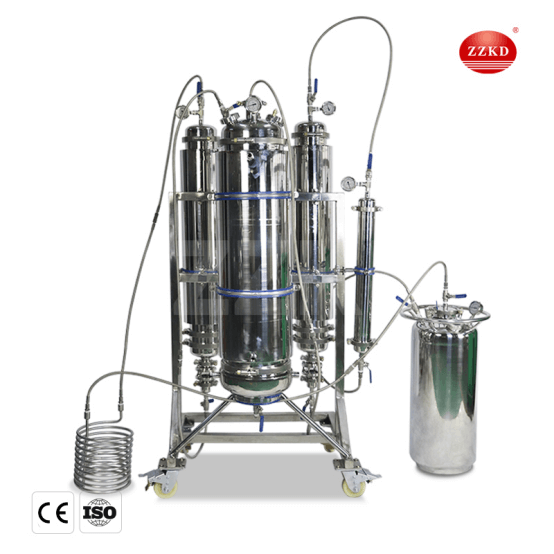

1.Closed Loop Extraction (CBD Oil Extraction Only)Get Latest Price

Closed-loop extraction, which has been used for years in the production of fragrances, beauty products, food additives and CBD essential oil extraction, minimises blast winds and provides a safe way to use flammable solvents.

Features:

Material: Both are made of 304 stainless steel, which is durable and has a long service life.

Capacity: 1Lb-80Lb, etc. Other sizes are optional

Surface treatment: mirror polished

Other application areas: beverages, herbs, CBD essential oils, cosmetics, pharmaceuticals, etc.

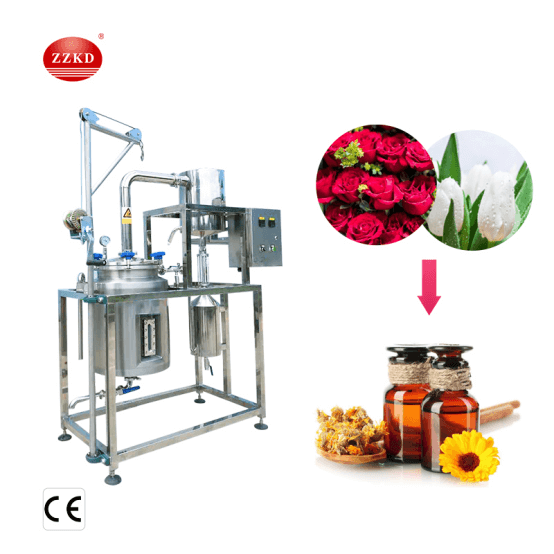

2.Essential Oil ExtractorGet Latest Price

The essential oil extraction machine is combined with the cash control system, the structure design is reasonable, and the performance is superior. The operation is simple and flexible, and the entire production can be easily completed by one person.

Features:

Material: The whole machine adopts 0CR18NI9TI and high-quality SS304 stainless steel

Volume: 10L-3000L, satisfying most usage scenarios

Control system: high degree of automation, and more precise temperature control

Components: extraction tank, material conveyor, electric steam boiler

Other configuration: cooling tower, circulating pump, air compressor, operating platform, stainless steel pipe and valve

3.Supercritical ExtractorGet Latest Price

The supercritical extractor equipment system has fast heat transfer speed and convenient temperature control. Suitable for the separation of volatile substances.

Features:

Material: The whole machine adopts 0CR18NI9TI and high-quality SS304 stainless steel

Volume: 10L-25L

Refrigeration system: equipped with semi-hermetic and fully-hermetic compressors, the cooling capacity meets the process requirements, and is suitable for the extraction and purification of heat-sensitive compounds. And can provide an inert environment to avoid product oxidation, without affecting the active ingredients of the extract.

Auxiliary Equipment

1.Circulating Water Vacuum PumpGet Latest Price

The circulating water is used as the working fluid to provide vacuum conditions for the working process.

Recycle water and save water resources.

Reasonable design, compact structure and safe packaging.

The movement is made of stainless steel and anti-corrosion materials.

2.Low Temperature Coolant Circulation PumpGet Latest Price

Provide a constant cold source for the equipment, adopt the principle of mechanical refrigeration for low temperature cooling, and the lowest temperature can reach -120℃.

Features:

The compressor has good cooling effect and long service life.

The circulation system is made of stainless steel, which has anti-corrosion and anti-rust functions.

Digital constant temperature display, microcomputer temperature control, simple and convenient operation.

It is easy to use and can work continuously.

Powerful Effects Of Essential Oils:

With the rapid economic development, people's thinking is also progressing. Some people spend money to learn health preservation knowledge and have a certain position in the field of health preservation. Some people study health preservation products. Of course, these are all for the benefit of mankind. Therefore, essential oil aromatherapy, which is popular all over the world, has entered people's attention, and essential oils have become a daily necessity for people's families.

Use 1: Apply Directly

The smear is mainly absorbed through the skin, so that the skin can directly absorb the essential oil; smear is divided into pure oil smear and diluted massage oil smear, which can improve fatigue and boost energy.

Use 2: Deploy Skin Care Products

You can add essential oils to lotions or creams and blend clockwise. After mixing, let it stand for a day, and use it after the essential oil and skin care products are fully mixed to strengthen the improvement effect.

You can add essential oils to lotions or creams and blend clockwise. After mixing, let it stand for a day, and use it after the essential oil and skin care products are fully mixed to strengthen the improvement effect.

Use 3: Shampoo And Conditioner

Add the essential oil to the shampoo, apply it evenly on the hair, massage gently, and then rinse with water; when conditioning the hair, adjust the ratio of the base oil to the essential oil, gently massage the scalp to absorb, and then rinse with the shampoo.

The potential value of essential oils is constantly being discovered. It has become a high-quality raw material for health care and beauty, bringing benefits to product manufacturers.