High Pressure Hydrogenation Reactor: Advancements and Applications

In the realm of chemical engineering, the high pressure reactor manufacturers stands as a significant technological marvel, playing a pivotal role in various industries. This versatile apparatus facilitates the process of hydrogenation, wherein hydrogen gas is introduced to a chemical compound, often under elevated pressures, to bring about molecular transformations. This article delves into the workings of a high-pressure hydrogenation reactor, its applications, and a compelling real-world case that exemplifies its importance.

Understanding the High-Pressure Hydrogenation Reactor

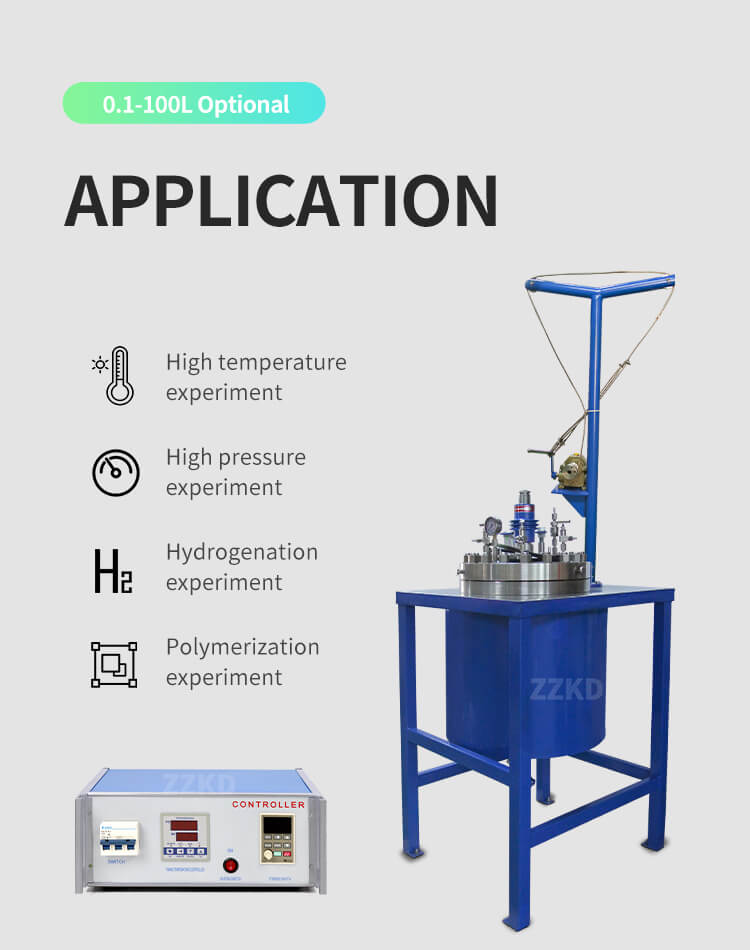

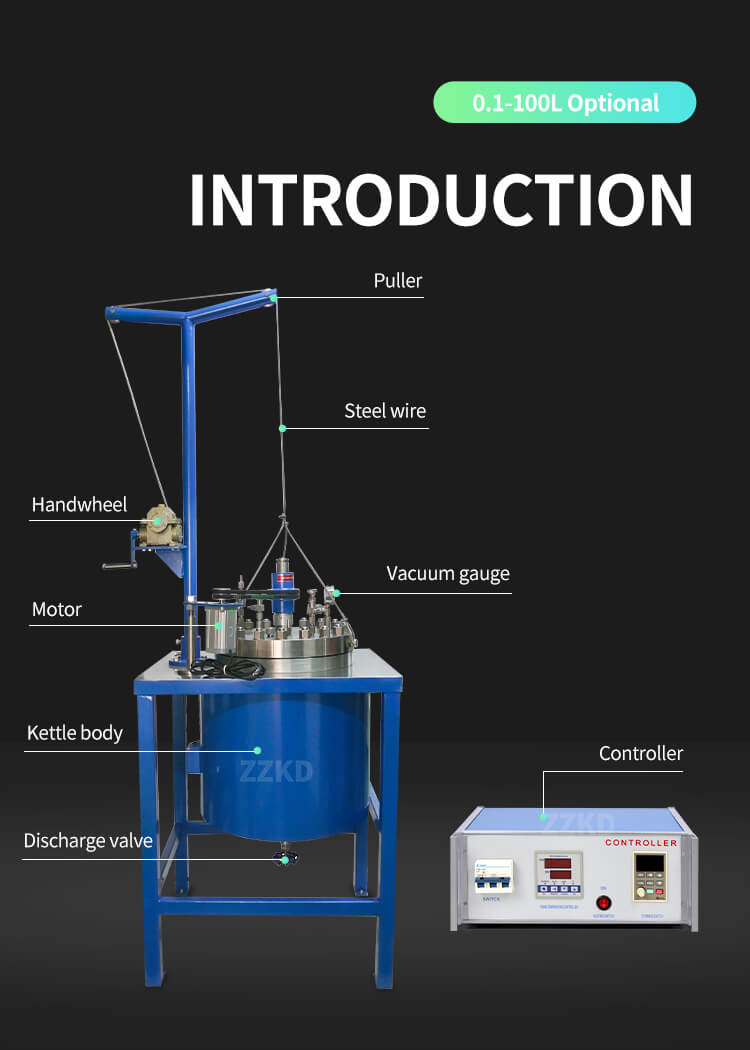

A high-pressure hydrogenation reactor is a specialized vessel designed to carry out chemical reactions under high pressures, often exceeding 1000 bar, and in the presence of hydrogen gas. This pressurized environment accelerates the hydrogenation process, allowing for precise control over reaction conditions and outcomes. The reactor typically consists of a robust cylindrical chamber, constructed from materials capable of withstanding extreme pressures, such as stainless steel or high-strength alloys. An array of valves, pressure gauges, and safety mechanisms ensures the controlled release of pressure and safe operation.

Subtle Dynamics of the Hydrogenation Process

The process of hydrogenation involves the introduction of hydrogen gas into the reactor, where it reacts with the target compound in the presence of a catalyst. This catalytic process leads to the formation of new chemical bonds, often resulting in reduced double or triple bonds in organic molecules. The high-pressure environment enhances the interaction between the hydrogen molecules and the compound, intensifying the reaction rate and yielding a more efficient conversion.

Applications Across Industries

The high-pressure hydrogenation reactor finds widespread application across multiple industries, each harnessing its potential for diverse purposes. One notable domain is the pharmaceutical sector, where it serves as an indispensable tool in drug development. Complex organic compounds can be selectively hydrogenated to create intermediates or final products, crucial for manufacturing various medications. Moreover, it aids in enantioselective hydrogenation, a key process in producing chiral molecules that are integral to many pharmaceuticals.

Case: Hydrogenation in Edible Oil Production

A compelling illustration of the high-pressure hydrogenation reactor's significance is its role in edible oil production. Vegetable oils, commonly used in cooking and food processing, often undergo hydrogenation to enhance their properties. In this case, the reactor facilitates the reduction of unsaturated fatty acids, converting them into more stable, saturated forms. This not only improves the oil's shelf life but also raises its melting point, rendering it suitable for various culinary applications, including frying and baking.

Advancements in Reactor Design and Operation

Over the years, the design and operation of high-pressure hydrogenation reactors have evolved, driven by technological innovations. Advanced computational simulations have enabled more accurate predictions of reaction kinetics, aiding in the optimization of operating conditions. Furthermore, improved catalyst development has led to enhanced selectivity, enabling the production of desired products with minimal undesired byproducts.

Environmental and Safety Considerations

While the high-pressure hydrogenation reactor offers a plethora of benefits, its operation demands meticulous attention to safety and environmental concerns. The utilization of hydrogen gas poses inherent risks, warranting rigorous safety protocols. Moreover, as the reactor often involves the use of precious metal catalysts, efficient recovery and recycling methods must be employed to minimize environmental impact.

Future Prospects and Emerging Trends

As the field of chemical engineering continues to advance, the high-pressure hydrogenation reactor is poised to witness further innovations. Researchers are exploring novel catalyst materials, including heterogeneous and biocatalysts, to enhance reaction efficiency and sustainability. Additionally, efforts are being directed towards the integration of renewable hydrogen sources, aligning with the global shift towards greener technologies.

Conclusion

In conclusion, the high-pressure hydrogenation reactor stands as a cornerstone of modern chemical engineering, facilitating transformative reactions across diverse industries. Its ability to operate under elevated pressures and efficiently catalyze hydrogenation reactions has led to significant advancements in pharmaceuticals, food production, and beyond. The case study of edible oil hydrogenation underscores its practical significance, while ongoing advancements promise a future of safer, more efficient, and environmentally conscious hydrogenation processes. As we continue to unlock the potential of this remarkable technology, it is evident that the high-pressure hydrogenation reactor will continue to shape the landscape of chemical synthesis and innovation.