High Pressure Batch Reactor: Advancing Laboratory Processes

Understanding High Pressure Batch Reactors

High pressure reactor manufacturers have revolutionized the field of laboratory equipment, bringing about significant advancements in various industries. These reactors, such as those offered by ZZKD Machinery and Instrument Equipment Co.,Ltd., are crucial tools for conducting chemical and biological processes under controlled conditions. With over 13 years of experience, ZZKD has established itself as a prominent player in producing and high pressure batch reactors .

High pressure batch reactors are designed to handle reactions that require elevated pressures, making them indispensable in fields like chemical synthesis, material testing, and pharmaceutical development. These reactors enable researchers and scientists to explore reactions that are otherwise impossible under standard atmospheric conditions. By allowing precise control over pressure, temperature, and other reaction parameters, these reactors contribute to the advancement of research and innovation across various sectors.

Key Features and Components

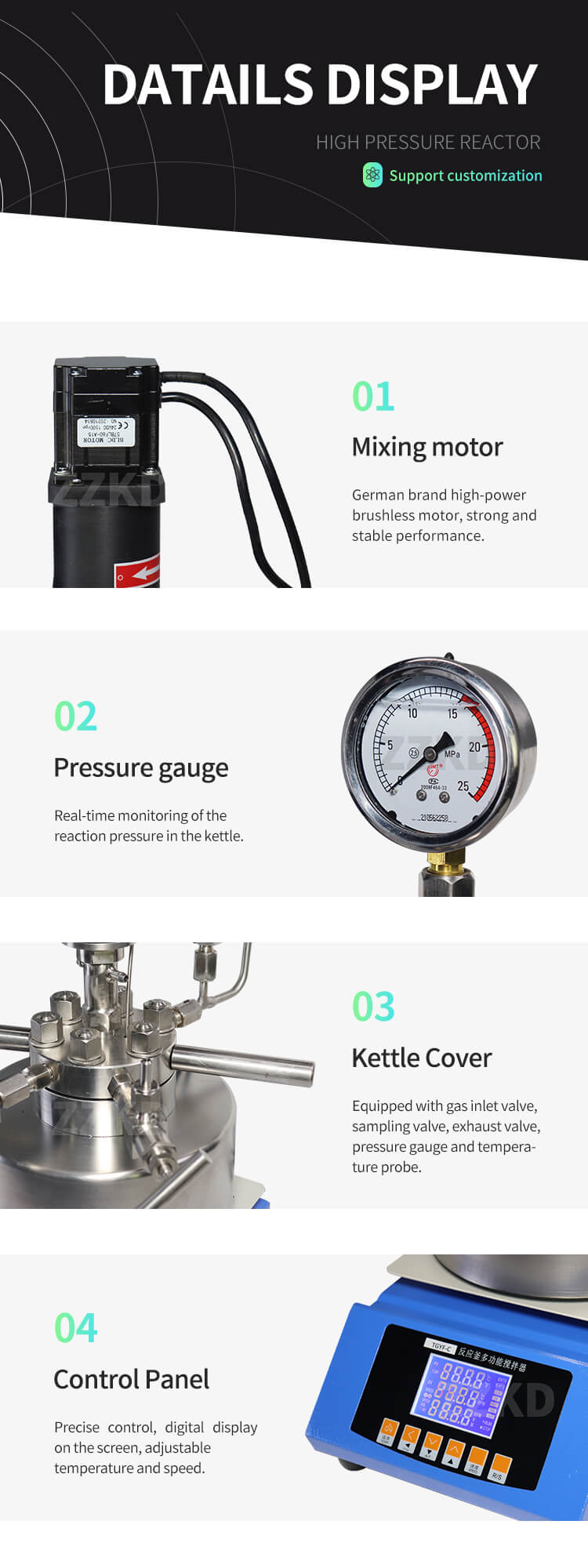

The design and functionality of high pressure batch reactors play a pivotal role in their effectiveness. Typically, these reactors consist of a robust pressure vessel, capable of withstanding the elevated pressures required for the reactions. A variety of safety features, including pressure relief valves and temperature sensors, ensure secure operation even during demanding processes. ZZKD's reactors, for instance, are engineered with utmost precision, adhering to ISO9001 and CE standards.

Moreover, the versatility of high pressure batch reactors is enhanced by the availability of interchangeable components. This adaptability allows researchers to customize reactors based on the specific requirements of their experiments. Stirrers, agitators, sampling systems, and pressure regulation mechanisms can be tailored to suit the needs of various reactions. As a result, ZZKD's high pressure batch reactors offer not only reliability but also flexibility in experimental design.

Applications in Chemical and Pharmaceutical Industries

The applications of high pressure batch reactors span across a wide spectrum of industries, prominently in the chemical and pharmaceutical sectors. In the chemical industry, these reactors facilitate the synthesis of specialty chemicals, polymers, and catalysts. The ability to manipulate pressure and temperature empowers chemists to optimize reaction kinetics and yield, ultimately leading to the development of innovative products.

In the pharmaceutical realm, high pressure batch reactors have accelerated drug discovery and development processes. The precise control over reaction conditions enables the synthesis of complex drug molecules and intermediates. This expedites the exploration of new drug candidates and their synthetic pathways. ZZKD's dedication to providing one-stop solutions aligns with the needs of pharmaceutical researchers, aiding them in their quest to bring life-saving medications to market efficiently.

Advantages Over Continuous Flow Systems

While continuous flow systems have their merits, high pressure batch reactors offer distinct advantages in certain scenarios. One notable advantage is the ability to handle a broader range of reactions, including those with varying reaction times or complex sequences. Batch reactors allow for greater control over reaction parameters and offer a more straightforward setup, making them suitable for processes that demand precise adjustments.

Additionally, high pressure batch reactors are advantageous for processes that require intermediate sampling and analysis. Researchers can monitor the reaction's progress at different time points, enabling real-time adjustments and enhancing the overall understanding of the reaction kinetics. This capability is particularly valuable in research and development phases where optimization and fine-tuning are essential.

Future Trends and Innovations

The future of high pressure batch reactors holds promising developments that will further expand their capabilities. One trend is the integration of automation and data analysis, enabling researchers to remotely control reactions and gather data in real-time. This not only increases efficiency but also allows for the execution of a higher number of experiments in a shorter timeframe.

Furthermore, the exploration of greener reaction conditions is gaining traction. High pressure batch reactors can play a pivotal role in developing environmentally friendly processes by optimizing reaction parameters for higher selectivity and lower waste production. ZZKD's commitment to innovation aligns with these trends, positioning them as a frontrunner in providing sustainable and technologically advanced solutions.

Conclusion: Pioneering Progress Through High Pressure Batch Reactors

High pressure batch reactors have emerged as indispensable tools for researchers and scientists across various industries. With their ability to facilitate complex reactions under controlled conditions, they have significantly advanced chemical synthesis, pharmaceutical development, and material testing. ZZKD Machinery and Instrument Equipment Co.,Ltd.'s expertise in manufacturing these reactors underscores their dedication to delivering high-quality, versatile, and customizable solutions to their global clientele.

As technology continues to evolve, high pressure batch reactors are poised to play an even more substantial role in shaping the future of laboratory processes. With the integration of automation, data analysis, and a focus on sustainable practices, these reactors will continue to drive innovation and progress, empowering researchers to unlock new realms of scientific discovery and industrial advancement.