Harga Mesin Spray Dryer Mini

Spray drying is a widely used method in various industries for drying liquid or slurry materials into a powder form. The process involves spraying the liquid feed into a hot air stream, where the droplets quickly dry and form fine particles. The harga mesin spray dryer mini is a critical equipment for many industries, including food, pharmaceuticals, ceramics, and chemicals. In this article, we will explore the spray drying process, the components of a spray dryer price, and the applications of this technology.

Spray Drying Process

The spray drying process involves four fundamental steps: atomization, drying, particle separation, and collection. In the first step, the liquid feed is atomized into droplets using a nozzle, rotary disc, or spray wheel. The size and distribution of the droplets are critical for the efficiency and quality of the process. A good spray dryer should have a narrow droplet size distribution to achieve uniform and consistent particle size.

In the second step, the droplets are introduced into a hot air stream in the drying chamber. The hot air evaporates the liquid content in the droplets, leaving behind solid particles. The temperature of the air and the residence time of the droplets in the drying chamber determine the degree of drying and the final particle properties. A typical harga mesin spray dryer mini can operate at temperatures ranging from 100 to 500 °C, and residence times from a few seconds to a few minutes.

In the third step, the solid particles are separated from the drying air using various methods, including cyclones, bag filters, or electrostatic precipitators. The separated air is then exhausted or recirculated to the drying chamber.

Finally, the solid particles are collected in a container or a conveying system for further processing or packaging. The particle properties, such as size, shape, and density, can be adjusted by changing the feed composition, the drying conditions, or the post-processing steps.

Components of a Harga Mesin Spray Dryer Mini

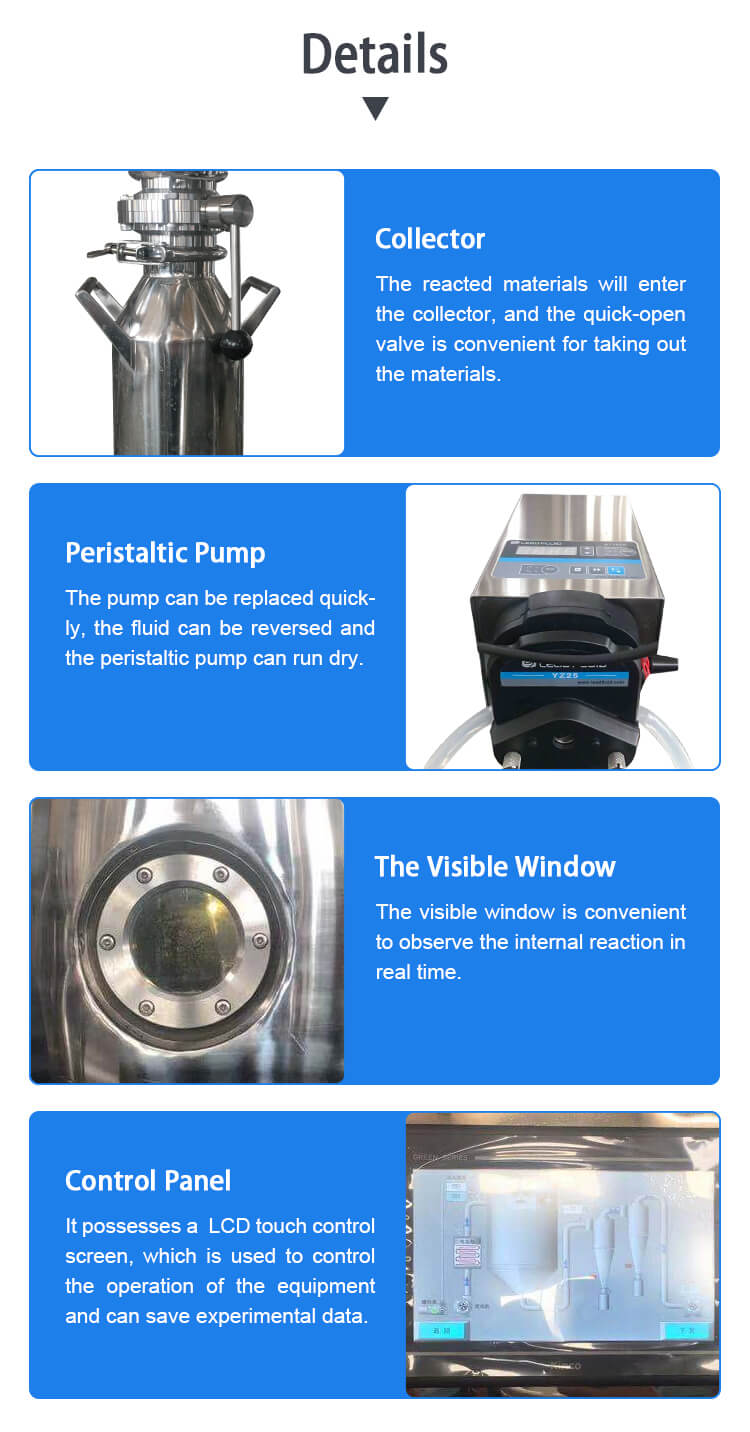

A typical harga mesin spray dryer mini consists of several components, including the atomizer, the drying chamber, the air heater, the air handling system, and the particle separation system.

The atomizer is the most critical component in the spray dryer, as it determines the droplet size distribution and the spray pattern. There are several types of atomizers, such as pressure nozzles, rotary atomizers, and centrifugal atomizers. Each type has its advantages and limitations, depending on the feed properties, the production rate, and the particle size requirements.

The drying chamber is where the droplets meet the hot air and undergo evaporation and solidification. The chamber can have various shapes and sizes, depending on the production volume and the feed properties. The design of the chamber should ensure efficient mixing of the droplets and the air, as well as uniform distribution of the heat and the airflow.

The air heater is responsible for heating the drying air to the desired temperature. The heater can use various fuels, such as natural gas, electricity, or steam. The efficiency and performance of the heater depend on the fuel type, the combustion system, and the heat recovery methods.

The air handling system comprises fans, ducts, and dampers, which control the airflow and the pressure inside the dryer. The system should ensure proper ventilation and minimize the formation of hot spots, condensation, or powder buildup.

The particle separation system is responsible for separating the solid particles from the drying air and recovering the excess air. The system can use various techniques, such as cyclones, bag filters, or electrostatic precipitators. The choice of the system depends on the particle size, the production rate, and the air quality requirements.

Applications of Harga Mesin Spray Dryer Mini

The harga mesin spray dryer mini is a versatile equipment that can be used in a wide range of industries for different applications. Here are some examples:

1. Food Industry: Spray drying is commonly used in the food industry to produce various food ingredients, such as milk powder, egg powder, coffee powder, and fruit powders. The process can preserve the flavor, color, and nutritional value of the food, and enhance their shelf life and stability.

2. Pharmaceutical Industry: Spray drying is widely used in the pharmaceutical industry to produce various drugs, such as antibiotics, inhalers, and vaccines. The process can improve the bioavailability, solubility, and stability of the drugs, and reduce the processing time and cost.

3. Ceramics Industry: Spray drying is commonly used in the ceramics industry to produce various ceramic powders, such as alumina, zirconia, and silica. The process can improve the homogeneity, sinterability, and packing density of the powders, and reduce the defects and impurities.

4. Chemical Industry: Spray drying is widely used in the chemical industry to produce various chemical powders, such as catalysts, pigments, and detergents. The process can improve the reactivity, dispersibility, and handling properties of the powders, and reduce the environmental impact and safety risks.

The harga mesin spray dryer mini is a critical equipment for many industries, as it enables the efficient and controlled conversion of liquid or slurry materials into powder form. The process involves atomization, drying, particle separation, and collection, and requires precise control of the feed composition, the drying conditions, and the particle properties. A typical harga mesin spray dryer mini consists of several components, including the atomizer, the drying chamber, the air heater, the air handling system, and the particle separation system. The choice of the components depends on the feed properties, the production volume, and the particle size requirements. The harga mesin spray dryer mini has numerous applications in various industries, such as food, pharmaceuticals, ceramics, and chemicals, and can improve the quality, performance, and sustainability of the products.