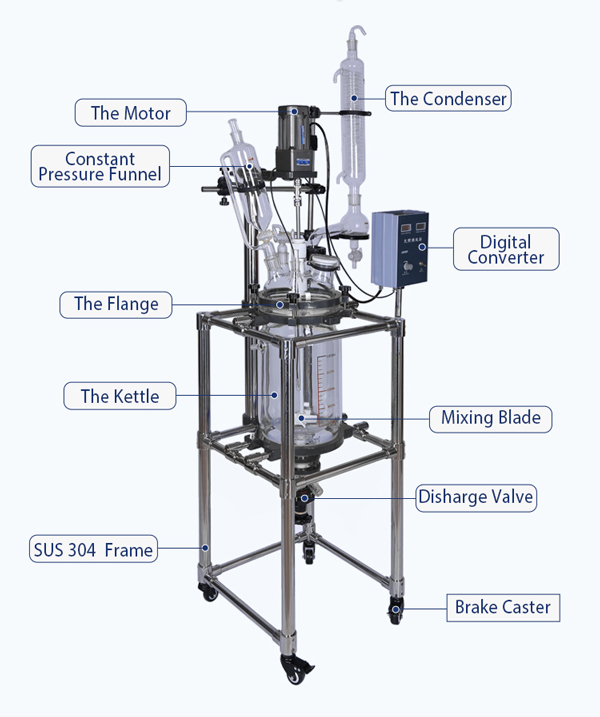

Laboratory Glass Reactor

The laboratory glass reactor can be used for high temperature reaction or low temperature reaction, and can also be evacuated to perform vacuum reaction. To react with different media in a glass explosion-proof reactor, first check whether the media corrodes the main material. Special orders are required for instantaneous reactions that produce a large amount of gas or high-temperature flammable and explosive chemical reactions, as well as high-pressure, high-temperature or medium containing chloride ions, fluorine ions, etc. that cause severe corrosion to stainless steel. Except that the kettle body and the jacket are made of transparent glass, the others are made of stainless steel or other metal materials. We produce and sell S1L-S5L laboratory glass reactor, S10L-S50L laboratory glass reactor, S80L-S100L laboratory glass reactor. Designed with double glass, it is powerful, inexpensive and durable.

When we use laboratory glass reactors, we are more or less worried. Some users think that the laboratory glass reactor is a kind of glass reaction equipment, which may cause problems such as flammability and explosion. In fact, it is made of borosilicate glass. As long as we can use and install our equipment as required, then we can rest assured that our equipment will perform its value. Some precautions for glass reactors are as follows:

1. Precautions for feeding: Since the reactor is an independent reaction frame, unlike an industrial reactor with a reaction platform, the reserved feeding port is small, and the feeding process is more difficult. For solid reagents, it is best to make a solution and add it to the kettle; for liquid reagents, it can be pumped into the kettle through a matching water pump or oil pump. Especially when adding reaction materials into the reaction kettle through a constant pressure dropping funnel or a common dropping funnel, a corresponding mobile ladder is required for the staff to add the sample.

2. Storage location: used as a reaction amplification test device, the volume is usually 50-150L, and the volume can be customized for specific conditions. Therefore, the scale of testing should not be underestimated. Since the body of the pot is made of glass, the support is made of stainless steel, and the legs are made of casters, the storage location needs to be carefully selected.

3. Safety settings: Due to its large reaction volume, the solvent concentration in the surrounding air is relatively high during use, so safety settings must be made. Due to its explosion-proof design, the explosion-proof motor, explosion-proof switch and explosion-proof power controller are mainly installed on the stirring motor and power controller.

Application of laboratory glass reactor:

The laboratory glass reactor can really realize the multi-purpose of the experiment, meet the needs of all aspects of different experiments, and can carry out:

1. Vacuum stirring reaction

2. High temperature, low temperature reaction

3. Mix and react at a constant speed

4. It can be distilled, refluxed and concentrated

5. Negative pressure operation, liquid separation function

6. The double-layer glass reactor is rectified by assembling the rectification column

7. Assemble into a glass reactor production line according to specific requirements.

8. For plant extraction, concentration has a good process effect

9. Stirring and separation, equipped with liquid separation device, the effect is obvious

10. Carry out reaction production of ultra-fine powder, hygienic medicine production, visible and clean.

11. The double-layer glass reaction kettle can replace the rotary evaporator for high-purity material concentration, equipped with ultrasonic stirring, and the reaction time is doubled.

12. Regardless of separation or synthesis, it is convenient to add materials and easy to operate