Exploring the Versatility of Small Autoclave Machines

Small autoclave machines play a crucial role in various industries, ensuring the sterilization and safety of equipment and materials. These compact devices are indispensable in laboratories, healthcare facilities, and many other settings where maintaining a sterile environment is of utmost importance. In this article, we delve into the fundamental role of high pressure reactor manufacturers and their wide-ranging applications.

In laboratories, small autoclave machines are employed for the sterilization of laboratory glassware, tools, and media. Their compact size and efficient performance make them an essential part of daily operations. Additionally, small autoclaves are used for sterilizing surgical instruments and medical equipment in hospitals and clinics, safeguarding the health and well-being of patients.

Small autoclaves are also utilized in the food industry to ensure that packaged goods remain free from harmful microorganisms. By subjecting food containers to high-temperature steam, these machines play a vital role in food safety, extending the shelf life of products and preventing foodborne illnesses.

Moreover, the research and development sector relies on small autoclave machines for the sterilization of growth media and laboratory equipment. Their versatility and ease of use make them indispensable tools for maintaining sterile conditions in various experimental setups.

Small autoclave machines are not limited to a single industry; they find applications in diverse fields, highlighting their importance in ensuring safety and sterility across the board.

The Working Mechanism of Small Autoclave Machines

Understanding how small autoclave machines operate is essential to appreciate their significance in various industries. These machines use the principles of steam sterilization to eliminate microorganisms and contaminants effectively.

The process begins with loading the items to be sterilized into the autoclave chamber. Once sealed, the machine introduces steam, raising the temperature and pressure inside the chamber. This combination of high temperature and pressure is lethal to bacteria, viruses, and other microorganisms, effectively rendering them inactive. The exposure time to these conditions depends on the specific requirements for sterilization.

Small autoclave machines feature controls that allow for precise adjustments of temperature and pressure, ensuring that sterilization occurs without damaging the materials being processed. After the set sterilization time, the machine gradually releases the pressure, and the chamber cools down. This gradual cooling prevents sudden temperature changes that could harm the sterilized items.

In addition to steam sterilization, some small autoclave machines offer pre-vacuum cycles that remove air from the chamber, further enhancing the effectiveness of the sterilization process. This ensures that even hard-to-reach areas of instruments and materials are thoroughly sterilized.

The working mechanism of small autoclave machines underscores their reliability in achieving sterile conditions in a wide range of applications.

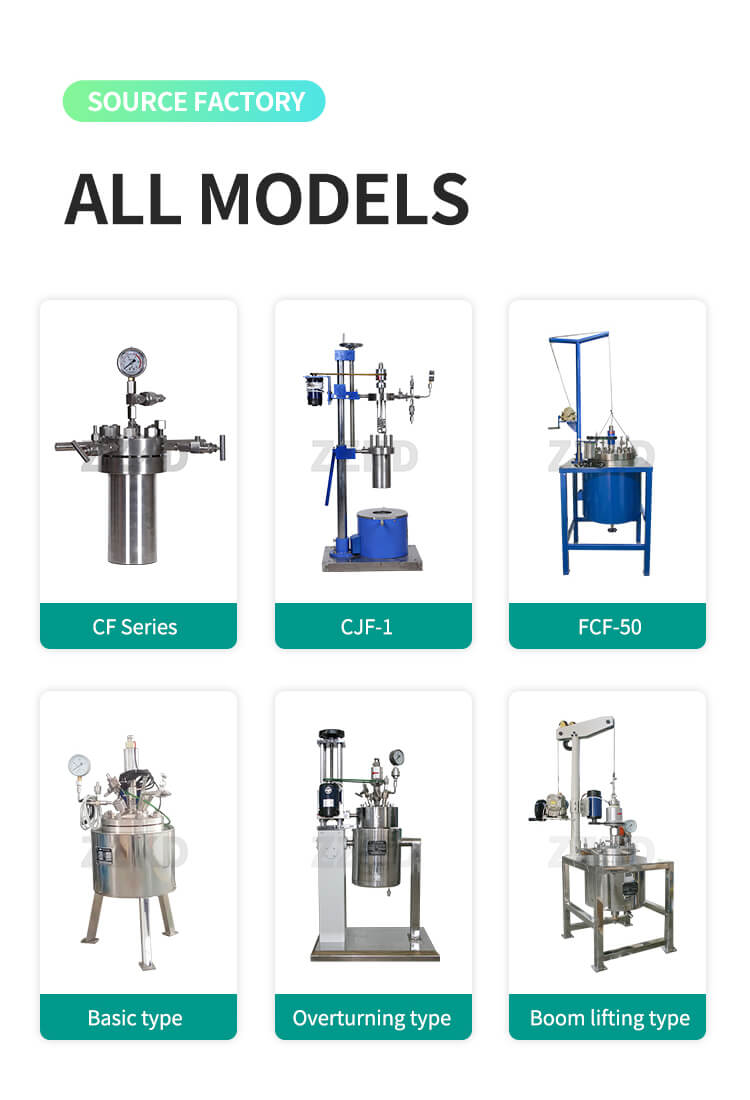

Diverse Small Autoclave Machine Types

Small autoclave machines come in various types and designs to cater to the specific needs of different industries. Understanding these variations can help businesses and professionals choose the right autoclave for their applications.

1. Benchtop Autoclaves:

Benchtop autoclaves are compact, portable, and ideal for laboratories with limited space. They are commonly used for the sterilization of laboratory glassware, media, and small equipment. Their small size and ease of use make them a popular choice for research and academic institutions.

2. Portable Autoclaves:

Portable autoclaves are designed for on-the-go sterilization needs. They are commonly used in field research, medical missions, and remote healthcare facilities. These autoclaves are compact and easy to transport, ensuring that sterilization can happen wherever it's needed.

3. Vertical Autoclaves:

Vertical autoclaves are known for their efficient use of space. They have a tall, narrow chamber design, making them suitable for sterilizing taller instruments and glassware. Their vertical orientation minimizes the floor space required, a valuable feature in busy laboratories.

4. Horizontal Autoclaves:

Horizontal autoclaves are designed for larger sterilization needs. They have a horizontal chamber layout, which allows for sterilizing bulkier equipment, such as fermentors and bioreactors. These autoclaves are common in industrial settings and research institutions with larger equipment.

5. Front-Loading Autoclaves:

Front-loading autoclaves have a convenient design for loading and unloading. Their front-opening doors make it easy to place items inside the chamber, which is advantageous when dealing with heavy or bulky materials. This type is commonly found in healthcare facilities and research labs.

6. Top-Loading Autoclaves:

Top-loading autoclaves are known for their efficient use of space and are particularly popular in small clinics and dental practices. Their compact design makes them a practical choice for businesses with limited floor space.

Small Autoclave Machines and Compliance

Compliance with industry regulations and standards is of paramount importance when using small autoclave machines. These standards are in place to ensure the safety of patients, researchers, and the general public. Small autoclaves must adhere to specific guidelines to guarantee that sterilization processes are effective and materials remain uncontaminated.

Sterilization standards often require routine testing and validation of autoclave cycles. This includes monitoring parameters such as temperature, pressure, and exposure time. Regular maintenance and calibration are essential to verify that the machine continues to operate within specified limits.

Additionally, operators should receive proper training in autoclave use and safety protocols. It is crucial that individuals responsible for operating these machines understand the significance of following procedures correctly to maintain sterility.

Ensuring compliance with relevant standards is not only a legal requirement but also a crucial aspect of guaranteeing the safety and reliability of small autoclave machines in diverse applications.

Future Trends in Small Autoclave Technology

The field of small autoclave machines continues to evolve as technology advances. Future trends in autoclave technology hold the promise of more efficient and eco-friendly sterilization methods.

One notable trend is the development of autoclaves with enhanced automation features. These machines may include touch-screen interfaces, remote monitoring, and data logging capabilities. Automation reduces the risk of human error and streamlines the sterilization process.

Another area of innovation is the use of alternative sterilization methods, such as hydrogen peroxide vapor or plasma sterilization. These technologies offer shorter cycle times and are less dependent on water, making them environmentally friendly options.

As sustainability becomes a global concern, manufacturers are exploring autoclaves with improved energy efficiency. These autoclaves may incorporate features like heat recovery systems and reduced water consumption to minimize their environmental impact.

In conclusion, small autoclave machines are indispensable tools that play a fundamental role in various industries. Understanding their working mechanism, types, compliance requirements, and future trends is essential for businesses and professionals to make informed decisions about their use. These compact devices have a far-reaching impact, ensuring the safety and sterility of equipment and materials across the world.