Ethyl Acetate Rotary Evaporator: Revolutionizing Chemical Processing

Introduction to Ethyl Acetate Rotary Evaporator

Ethyl acetate, a widely used solvent in various industries, demands efficient and safe processing methods. Enter the Ethyl Acetate Rotary Evaporator, a groundbreaking device that has transformed the way we handle this volatile organic compound. In this introduction, we'll explore the basic principles of the rotovap for sale and its specific application for ethyl acetate.

Rotary evaporators, commonly known as rotavaps, are used in chemical laboratories for the efficient and gentle removal of solvents from samples through evaporation. Particularly, when dealing with ethyl acetate, a rotary evaporator ensures controlled handling, enhancing safety and efficiency.

The Design and Functionality

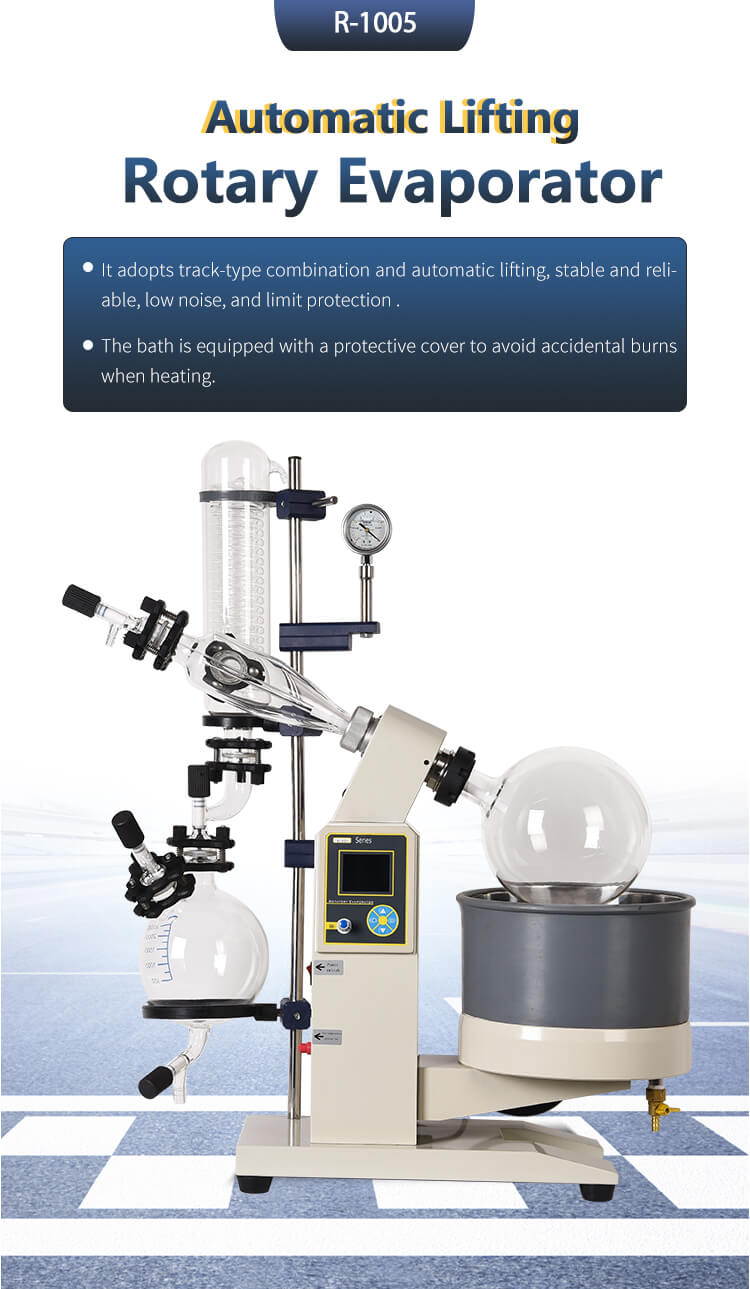

Understanding the design of an ethyl acetate rotary evaporator is crucial. This section delves into its construction, which includes a rotating flask, a water or oil bath, and a vacuum system, among other components. We'll explore how these parts work in unison to achieve optimal evaporation of ethyl acetate.

The rotating flask facilitates the even distribution of the solvent, ensuring efficient evaporation. The temperature-controlled water or oil bath heats the flask, while the vacuum system reduces the pressure, allowing ethyl acetate to evaporate at lower temperatures. This process minimizes the risk of overheating sensitive compounds.

Applications in Various Industries

Ethyl acetate rotary evaporators are not limited to chemical laboratories. This segment highlights their versatility across different sectors, including pharmaceuticals, food and beverage, and cosmetics. In each industry, the evaporator plays a crucial role in quality control, product development, and research.

In the pharmaceutical industry, for example, it's used for the purification and concentration of compounds. In the food sector, it aids in flavor extraction. The precise control offered by these evaporators makes them indispensable tools in these fields.

Advantages Over Traditional Methods

Switching from conventional evaporation methods to a rotary evaporator offers numerous benefits. This part of the article will outline the advantages, such as increased efficiency, improved safety, and higher product quality, when using ethyl acetate rotary evaporators.

One of the key advantages is the ability to perform evaporation under reduced pressure, which is particularly beneficial for heat-sensitive compounds. This feature, along with the controlled environment, reduces the risk of decomposition and ensures the integrity of the final product.

Choosing the Right Model

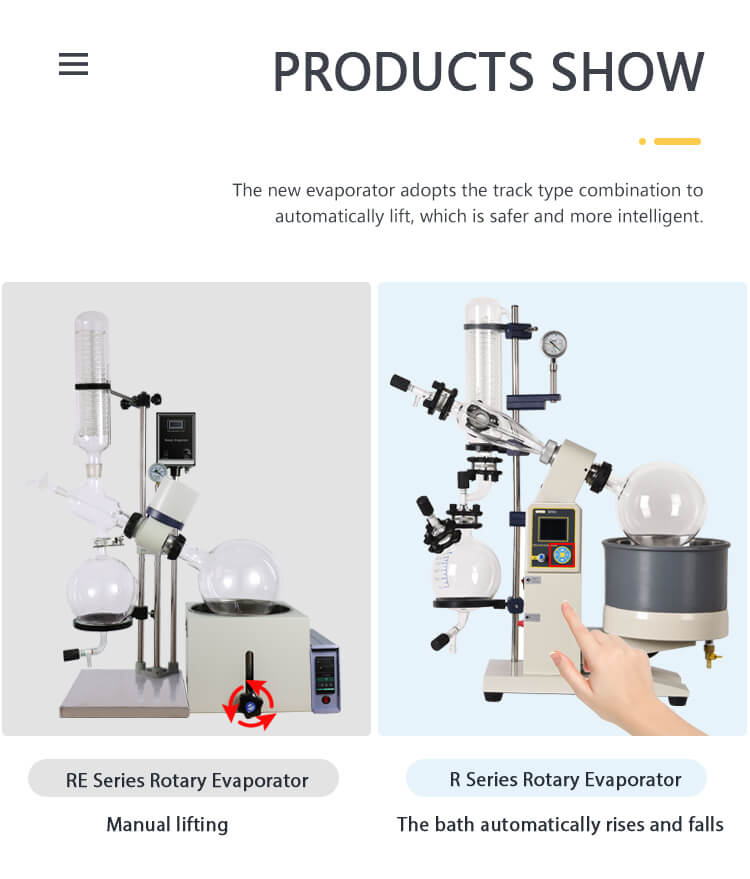

Selecting the appropriate ethyl acetate rotary evaporator for your needs can be daunting. This section provides guidance on the factors to consider, including size, capacity, and additional features like digital control panels or automated lift systems.

It’s important to consider the scale of operations and the specific requirements of the tasks at hand. For instance, larger models are better suited for industrial-scale operations, while compact models are ideal for smaller laboratories.

Maintenance and Safety Tips

Proper maintenance and adherence to safety protocols are vital for the longevity and safe operation of an ethyl acetate rotary evaporator. Here, we’ll provide essential tips on cleaning, routine checks, and safety measures to prevent accidents and ensure smooth operation.

Regular maintenance includes checking seals, cleaning the glass parts, and ensuring the vacuum system is free from leaks. Safety tips cover proper handling of ethyl acetate, understanding the risks associated with vacuum operations, and the importance of using the equipment within its specified parameters.

Conclusion: The Future of Ethyl Acetate Processing

In conclusion, the ethyl acetate rotary evaporator stands as a testament to innovation in chemical processing. Its precision, efficiency, and versatility make it an essential tool in various industries. As technology advances, we can expect even more sophisticated models, further enhancing the capabilities and applications of these devices.

Call to Action

For those interested in exploring the possibilities of an ethyl acetate rotary evaporator, ZZKD Machinery and Instrument Equipment Co., Ltd offers a range of high-quality models tailored to meet your specific needs. Visit our website to learn more about our products and how they can benefit your operations. Our experienced team is ready to provide you with professional advice and solutions, ensuring you make the most out of this revolutionary equipment.