Ethanol Extraction Using Rotary Evaporator

In the dynamic field of science and technology, innovative methods are continually reshaping how we approach various processes. A prime example of this innovation is the use of a rotary evaporator, often referred to as a 'rotovap,' for ethanol extraction. This technique has revolutionized the extraction process, offering a blend of efficiency, purity, and safety.

The Principle of Rotary Evaporation

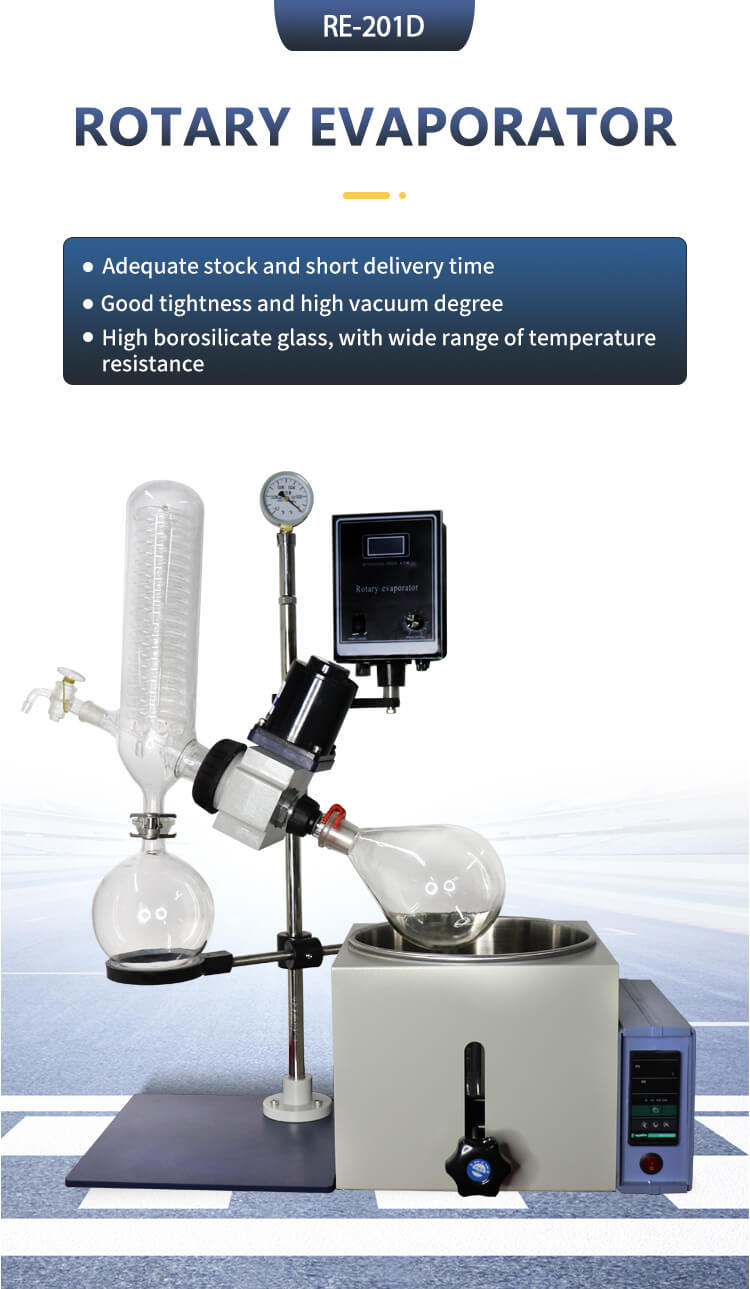

Ethanol extraction using a rotary evaporator operates on the principle of rapid evaporation of solvents under reduced pressure. The rotovap consists of a rotating flask, which increases the surface area of the liquid, speeding up the evaporation process. By employing a vacuum, the boiling point of ethanol is significantly lowered, allowing for efficient extraction at lower temperatures. This is crucial in preserving the integrity of heat-sensitive compounds.

Advantages in Various Fields

The application of a rotary evaporator in ethanol extraction has been a game-changer in industries like pharmaceuticals, food, and fragrance. This method ensures a high purity of the extracted compounds, making it ideal for producing concentrated extracts. The controlled and gentle removal of ethanol also guarantees the preservation of delicate substances, which could otherwise degrade under traditional extraction methods.

The Process of Ethanol Extraction

Ethanol extraction using a rotary evaporator involves several key steps:

1. Solvent Selection: Ethanol, known for its effectiveness and relative safety, is the solvent of choice.

2. Mixing: The material to be extracted is mixed with ethanol, allowing the solvent to dissolve the desired compounds.

3. Rotary Evaporation: The mixture is then placed in the rotovap. As it rotates, the evaporator creates a thin film of the mixture, expediting the evaporation of ethanol.

4. Condensation: The evaporated ethanol is then cooled and condensed back into a liquid form, separating it from the extract.

5. Collection: The concentrated extract is collected, and the ethanol can be reused, making this an environmentally friendly process.

Technological Innovations and Availability

Continual technological advancements have made rotary evaporators more accessible and efficient. Modern rotovaps feature digital temperature controls, vacuum regulation, and safety mechanisms. For those interested in adopting this technology, there are options for a rotovap for sale from various scientific equipment suppliers. These models range from basic to advanced, catering to different needs and scales of operation.

The Future of Ethanol Extraction

The future of ethanol extraction using rotary evaporators looks promising. As research progresses, we can expect more refined models with higher efficiencies and even more specialized applications. This method stands as a testament to how technological advancements can bring about safer, cleaner, and more efficient practices in scientific processes.

Conclusion

The use of a rotary evaporator for ethanol extraction symbolizes a significant step forward in scientific and technological progress. Its impact across various industries highlights its versatility and efficiency. As science continues to evolve, methods like these will pave the way for more innovative and sustainable practices.