Efficient Homogenization: Laboratory Vacuum Mixer Unveiled

Laboratory vacuum mixer homogenizer is an essential tool in scientific research and industrial processes. This versatile equipment plays a crucial role in mixing and homogenizing various substances with precision and efficiency. In this article, we will explore the features, applications, and benefits of a laboratory vacuum mixer homogenizer, shedding light on its significant contributions to scientific advancements.

I. Understanding Laboratory Vacuum Mixer Homogenizer

A. What is a Laboratory Vacuum Mixer Homogenizer?

A laboratory vacuum mixer homogenizer is a sophisticated device designed to facilitate mixing, blending, and homogenization of substances in a controlled environment. It consists of a mixing vessel, a vacuum system, a homogenizing unit, and an array of advanced controls. This equipment enables the thorough dispersion and uniform distribution of ingredients, ensuring consistent results in various applications.

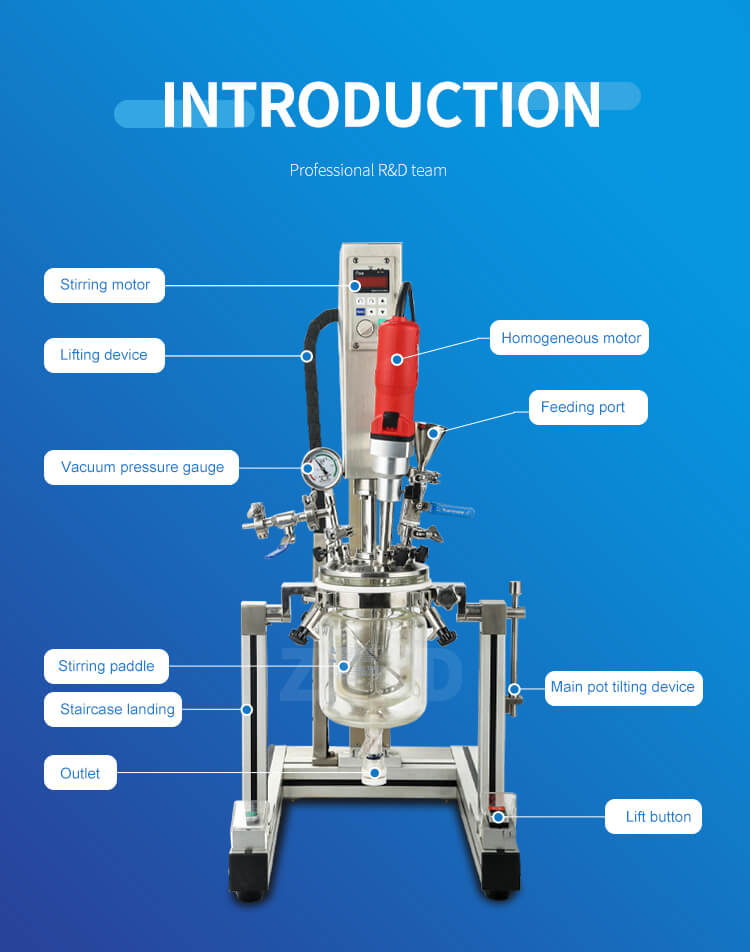

B. Components and Working Principle

The laboratory vacuum mixer homogenizer comprises several key components. The mixing vessel, typically made of stainless steel, provides a sturdy and hygienic environment for the mixing process. The vacuum system creates a low-pressure environment within the vessel, aiding in the removal of air bubbles and preventing oxidation.

The homogenizing unit consists of a powerful motor, a rotor-stator assembly, and adjustable blades. The motor drives the blades at high speeds, generating shear forces and turbulence, resulting in efficient mixing and emulsification. The adjustable blades allow for customization based on the desired viscosity and mixing requirements.

C. Key Features and Functionality

Laboratory vacuum mixer homogenizers offer a range of features to enhance performance and flexibility. These may include:

1. Variable Speed Control: The ability to adjust mixing speeds ensures optimal results for different sample types and viscosities.

2. Temperature Control: Some models incorporate heating or cooling capabilities, enabling precise control over the process temperature.

3. Programmable Operation: Advanced laboratory vacuum mixer homogenizers allow for the creation and storage of customized mixing programs, enhancing reproducibility and efficiency.

4. Safety Measures: Safety features such as overheat protection, automatic shutdown, and secure lid locking mechanisms ensure operator safety and protect the equipment.

II. Applications of Laboratory Vacuum Mixer Homogenizer

A. Pharmaceutical Industry

In the pharmaceutical industry, laboratory vacuum mixer homogenizers play a vital role in formulating medications, creating stable emulsions, and ensuring uniform distribution of active ingredients. They are used in the production of creams, ointments, gels, and other topical formulations. The precise control over mixing parameters provided by these devices contributes to consistent product quality and improved drug efficacy.

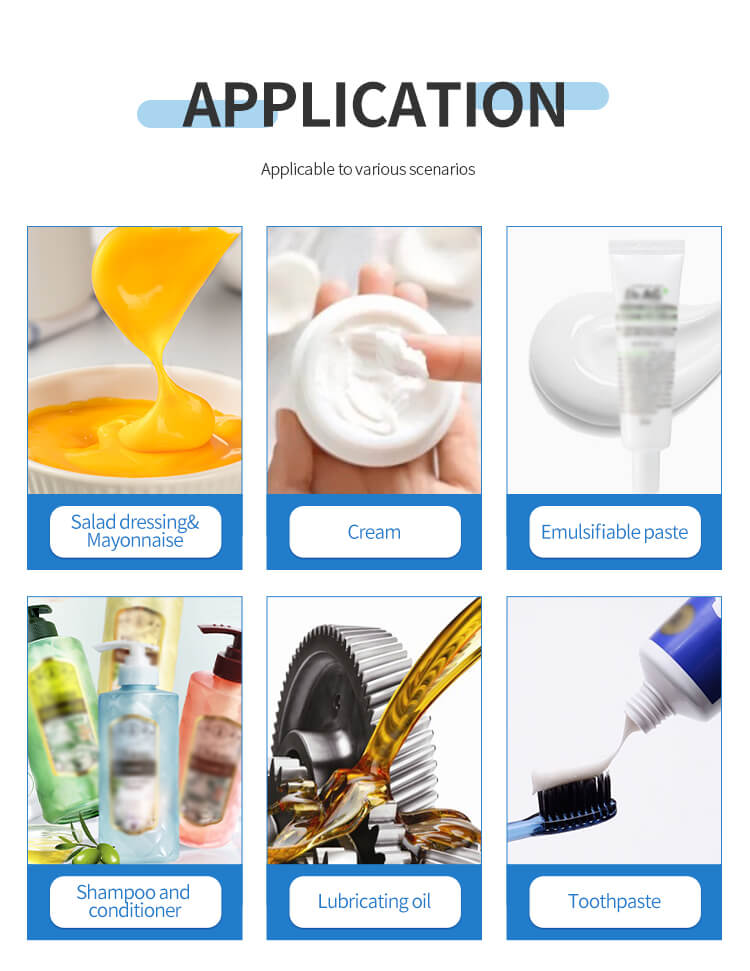

B. Food and Beverage Industry

Laboratory vacuum mixer homogenizers find extensive application in the food and beverage industry. They are employed in the production of sauces, dressings, mayonnaise, and dairy products to achieve the desired texture, stability, and sensory characteristics. These homogenizers aid in the efficient dispersion of emulsifiers, stabilizers, and other additives, resulting in smooth and homogeneous products.

C. Chemical and Petrochemical Industry

Laboratory vacuum mixer homogenizers are utilized in the chemical and petrochemical industry for various mixing and blending processes. They are particularly valuable in the production of paints, coatings, adhesives, and polymers, ensuring the homogeneous distribution of pigments, additives, and fillers. The equipment's ability to handle high-viscosity materials and generate intense shear forces makes it suitable for demanding applications.

D. Cosmetics Industry

In the cosmetics industry, laboratory vacuum mixer homogenizers are essential for formulating creams, lotions, and other personal care products. These devices ensure the uniform dispersion of active ingredients, fragrances, and colorants, resulting in consistent product quality. The precise control over mixing parameters enables the creation of stable emulsions, enhancing the shelf life and sensory attributes of cosmetic formulations.

E. Research and Development

Laboratory vacuum mixer homogenizers are extensively used in research and development laboratories across various disciplines. They enable scientists to experiment with different formulations, study the effects of mixing parameters, and optimize processes. These homogenizers play a crucial role in developing new materials, investigating drug delivery systems, and advancing scientific knowledge in diverse fields.

III. Advantages of Laboratory Vacuum Mixer Homogenizer

A. Enhanced Mixing Efficiency

Laboratory vacuum mixer homogenizers offer superior mixing efficiency compared to conventional mixing methods. The intense shear forces and turbulence generated by the homogenizing unit ensure rapid and thorough dispersion of ingredients, resulting in shorter processing times and improved productivity.

B. Homogenization of Viscous Substances

The powerful motor and adjustable blades of laboratory vacuum mixer homogenizers can effectively homogenize highly viscous substances. This capability is particularly valuable in industries such as cosmetics, where the uniform distribution of ingredients in thick creams or lotions is crucial.

C. Improved Product Quality

The precise control over mixing parameters provided by laboratory vacuum mixer homogenizers contributes to improved product quality. The ability to maintain consistent mixing conditions ensures uniform distribution of ingredients, resulting in products with enhanced stability, texture, and sensory attributes.

D. Time and Cost Savings

The efficient mixing and homogenization capabilities of laboratory vacuum mixer homogenizers lead to significant time and cost savings in production processes. The reduced processing times and improved productivity translate into higher throughput and reduced labor costs, making these devices a valuable investment.

E. Customization and Scalability

Laboratory vacuum mixer homogenizers offer customization options to meet specific process requirements. The ability to adjust mixing parameters, such as speed, time, and temperature, allows users to optimize formulations and achieve desired results. Additionally, these devices are scalable, enabling seamless transition from laboratory-scale experiments to larger production volumes.

IV. Choosing the Right Laboratory Vacuum Mixer Homogenizer

A. Considerations for Selection

When choosing a laboratory vacuum mixer homogenizer, several factors should be considered to ensure optimal performance and compatibility with the intended applications. Key considerations include:

1. Sample Volume and Viscosity: Determine the expected sample volume range and the viscosity of the materials to select a homogenizer with the appropriate capacity and power.

2. Speed and Power Options: Assess the range of speed and power options available in different models to ensure compatibility with the desired mixing requirements.

3. Material Compatibility: Consider the compatibility of the mixing vessel, blades, and seals with the substances being processed to prevent contamination or damage.

4. Safety Features: Evaluate the presence of safety features, such as emergency stop buttons, lid interlocks, and overheat protection, to prioritize operator safety.

B. Sample Volume and Viscosity

The volume and viscosity of the samples are critical factors when selecting a laboratory vacuum mixer homogenizer. Smaller benchtop models are suitable for laboratory-scale experiments, while larger floor-standing units are designed for higher volumes. Similarly, highly viscous materials may require more powerful homogenizers to achieve efficient mixing and dispersion.

C. Speed and Power Options

Laboratory vacuum mixer homogenizers offer various speed and power options to accommodate different mixing requirements. Consider the range of adjustable speeds available in a homogenizer to ensure it can handle both gentle mixing and intense homogenization. Additionally, evaluate the power rating to ensure it is sufficient for the viscosity and volume of the samples.

D. Material Compatibility

Ensure that the materials of construction for the mixing vessel, blades, and seals are compatible with the substances being processed. Stainless steel vessels and blades are commonly used due to their durability, corrosion resistance, and ease of cleaning. For specialized applications, such as those involving corrosive chemicals, it may be necessary to choose a laboratory vacuum mixer homogenizer with specific material compatibility options.

E. Safety Features

Safety should be a top priority when selecting a laboratory vacuum mixer homogenizer. Look for features such as emergency stop buttons, lid interlocks, and overheat protection mechanisms. These safety measures protect both the operator and the equipment, minimizing the risk of accidents or damage during operation.

V. Operating a Laboratory Vacuum Mixer Homogenizer

A. Safety Precautions

Before operating a laboratory vacuum mixer homogenizer, it is essential to follow proper safety precautions. Some key safety measures include:

1. Familiarize yourself with the equipment's safety features and emergency shut-off procedures.

2. Wear appropriate personal protective equipment, such as gloves, goggles, and lab coats, to protect against potential hazards.

3. Ensure that the equipment is properly grounded to prevent electrical hazards.

4. Follow the manufacturer's instructions for safe operation and maintenance of the equipment.

B. Setup and Calibration

Proper setup and calibration are crucial for achieving accurate and consistent results with a laboratory vacuum mixer homogenizer. Follow these steps for effective setup:

1. Ensure the equipment is clean and free from any residue or contaminants.

2. Assemble the mixing vessel, blades, and seals according to the manufacturer's instructions.

3. Calibrate the equipment to ensure accurate measurement of mixing parameters, such as speed and temperature, if applicable.

C. Loading and Mixing Samples

Loading and mixing samples in a laboratory vacuum mixer homogenizer require careful attention to detail. Follow these guidelines:

1. Measure and add the desired quantity of each component to the mixing vessel, following the recommended sequence.

2. Securely close the lid of the vessel to prevent any leaks or spills during operation.

3. Set the desired mixing parameters, such as speed and duration, based on the specific requirements of the process.

4. Start the equipment and closely monitor the mixing process, making any necessary adjustments to achieve the desired results.

D. Cleaning and Maintenance

Proper cleaning and maintenance of a laboratory vacuum mixer homogenizer ensure its longevity and reliable performance. Consider the following practices:

1. After each use, thoroughly clean the equipment, including the mixing vessel, blades, and seals, to remove any residual materials.

2. Use appropriate cleaning agents and procedures recommended by the manufacturer.

3. Regularly inspect and replace worn-out or damaged components to maintain the equipment's efficiency and prevent contamination.

4. Follow the manufacturer's guidelines for routine maintenance tasks, such as lubrication, motor inspection, and calibration checks.

VI. Recent Technological Advancements in Laboratory Vacuum Mixer Homogenizer

A. Automation and Control Systems

Modern laboratory vacuum mixer homogenizers are equipped with advanced automation and control systems. These systems enable precise and repeatable mixing processes by allowing users to program and store customized mixing parameters. Automation also reduces the risk of human error and enhances overall process efficiency.

B. Integration of IoT and AI

The integration of Internet of Things (IoT) technology and Artificial Intelligence (AI) has revolutionized laboratory equipment, including vacuum mixer homogenizers. IoT connectivity allows remote monitoring and control of the equipment, providing real-time data and notifications. AI algorithms analyze process data, optimizing mixing parameters, and providing insights for improved performance.

C. Advanced Monitoring and Analysis

Laboratory vacuum mixer homogenizers now offer advanced monitoring and analysis capabilities. Built-in sensors and data acquisition systems capture key parameters such as temperature, pressure, and torque during the mixing process. This data can be analyzed to identify trends, optimize formulations, and troubleshoot potential issues.

The laboratory vacuum mixer homogenizer is a versatile and indispensable tool in various industries, offering precise mixing and homogenization capabilities. Its applications span across pharmaceuticals, food and beverages, chemicals, cosmetics, and research and development sectors. The advantages of using a laboratory vacuum mixer homogenizer include enhanced efficiency, improved product quality, and significant time and cost savings. When choosing a laboratory vacuum mixer homogenizer, considerations such as sample volume, viscosity, speed options, and safety features should be evaluated. By following proper operating procedures and embracing technological advancements, users can maximize the potential of this equipment and drive scientific progress.