Chiller Cooler | ZZKD Machinery

DLSB series low-temperature coolant circulation pump, also known as chiller cooler, is a low-temperature liquid circulation equipment that adopts mechanical refrigeration. It has the function of providing low-temperature liquid and low-temperature water bath. Combined with rotary evaporator, vacuum freeze-drying oven, circulating water multi-purpose vacuum pump, magnetic stirrer and other instruments, it can carry out multi-functional low-temperature chemical reaction operations and drug storage. The large-scale low-temperature coolant circulation pump with constant flow, constant pressure and circulating fluid can meet the cooling needs of electron microscopes, electron probes, ultra-high vacuum sputtering instruments, X-ray machines, lasers, accelerators and other expensive instruments and equipment. For large-scale equipment such as high-purity metals, rare substance purification, environmental experiments, magnetron sputtering, and vacuum coating, cooling water that meets the dual requirements of temperature and water quality can be provided. The equipment is especially suitable for chemical, biological, and physical laboratories that need to maintain low temperature and work at room temperature. device of.

The specific combination method of chiller cooler and rotary evaporator:

1. Turn on the chiller cooler. Take care to press the power button first, then the cool down button, when the temperature drops to the desired temperature, the cycle begins.

2. Turn on the pump to circulate the water.

3. Install the decanter and fix it with clips. Turn on the vacuum pump and start to rotate after a certain vacuum.

4. Adjust the height and rotation speed of the distillation bottle, and set the appropriate temperature of the water bath.

5. After steaming, first stop the rotation, then turn on the air, stop the water pump, and take out the distillation bottle.

6. Stop the chiller cooler, turn off the circulating water of the water pump, pour out the solvent in the collection bottle, and clean the buffer ball and the collection bottle.

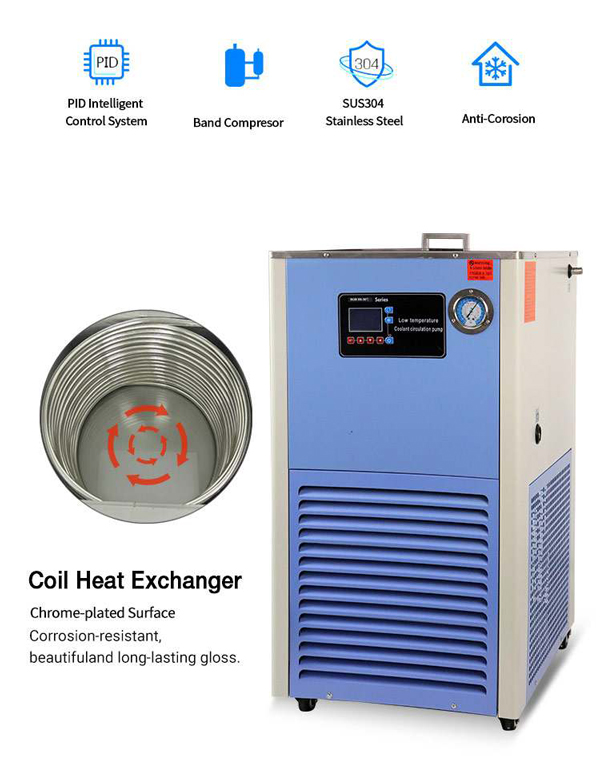

Chiller cooler performance characteristics:

1. The chiller coolers all use original high-quality components, special relays for refrigeration units, capacitors, protectors, refrigeration components, etc.;

2. Humanized man-machine interface, digital temperature display, microcomputer, temperature control, easy and flexible operation, eye-catching;

3. Adopt the fully enclosed compressor unit and circulating water pump of international manufacturers and installation parts, with advanced performance and stable quality;

4. The circulation system adopts anti-corrosion materials; it has the function of reducing the pollution of high-temperature liquid, and has the function of anti-rust and anti-corrosion;

5. The operation is convenient, and it can be completed directly in the machine only with the electric stirrer, and the operation is flexible and convenient;

6. The cooler of the chiller is tested at the specified temperature (-40)-60)*C, and the cooling liquid can be pumped to the designated place of use, and there is a circulating pump inside. easy and convenient;

Chiller Chiller Precautions:

When the working temperature of the chiller cooler is low, care should be taken not to open the upper cover and keep your hands away from the water tank to prevent frostbite; after use, turn off all switches and cut off the power supply; when the liquid is circulating externally, the customer should pay special attention to the firmness of the connection of the outlet pipe Sex, prevent falling off, so as not to leak. Instruments should be cleaned regularly. When not in use for a long time, the medium in the tank should be emptied and wiped clean to keep the work surface and operation panel clean.