Best Industrial Spray Dryers for Sale

In the fast-paced world of industrial manufacturing, the demand for efficient, reliable, and cost-effective production solutions is ever-growing. Among the various technologies available, industrial spray dryers stand out as a cornerstone for many industries. From pharmaceuticals to food processing, and from chemicals to ceramics, spray drying has become an indispensable method for creating high-quality powders with precise particle characteristics. If you are in the market for an industrial spray dryer or exploring the best spray dryer for sale, this comprehensive guide will provide you with everything you need to know.

What is an Industrial Spray Dryer?

An industrial spray dryer is a piece of equipment that converts liquid materials into dry powders by rapidly drying them with a hot gas. This process, known as spray drying, involves three fundamental steps:

1. Atomization: The liquid feed is atomized into fine droplets using various methods such as rotary, pressure, or ultrasonic atomizers.

2. Drying: The atomized droplets are introduced into a drying chamber where they come into contact with hot air or gas. The rapid evaporation of moisture from the droplets forms dry particles.

3. Separation: The dry particles are separated from the drying air using cyclones, filters, or electrostatic precipitators, and then collected.

This method is widely used because it allows for the production of powders with specific particle sizes, moisture content, and bulk density, tailored to meet the exact needs of various applications.

The Advantages of Industrial Spray Dryers

Industrial spray dryers offer numerous advantages that make them a preferred choice for many manufacturers:

Efficiency: Spray drying is a continuous process that can handle large volumes of material with high throughput rates, making it suitable for industrial-scale production.

Uniform Particle Size: The atomization process allows for precise control over particle size distribution, ensuring consistent product quality.

Retention of Properties: The rapid drying process minimizes thermal degradation of sensitive materials, preserving their nutritional, chemical, and physical properties.

Versatility: Spray dryers can process a wide range of materials, including heat-sensitive substances, slurries, solutions, and emulsions.

Key Considerations When Buying a Spray Dryer

When looking for spray dryers for sale, it is essential to consider several key factors to ensure you select the right equipment for your needs:

1. Capacity: Determine the production capacity required to meet your manufacturing goals. Spray dryers are available in various sizes, from laboratory-scale units to large industrial systems.

2. Material Properties: Consider the characteristics of the material you need to dry, such as viscosity, thermal sensitivity, and corrosiveness, to select a suitable dryer configuration.

3. Energy Efficiency: Evaluate the energy consumption of the dryer, as this can significantly impact operational costs. Look for models with advanced energy-saving features.

4. Ease of Cleaning: For industries like food and pharmaceuticals, hygiene is paramount. Choose spray dryers designed for easy cleaning and minimal contamination risk.

5. Control Systems: Modern spray dryers come equipped with sophisticated control systems that allow for precise monitoring and adjustment of drying parameters, ensuring optimal performance.

Top Spray Dryers for Sale in the Market

With a myriad of options available, finding the best spray dryer for sale can be a daunting task. Here, we highlight some of the top industrial spray dryers renowned for their performance, reliability, and innovative features.

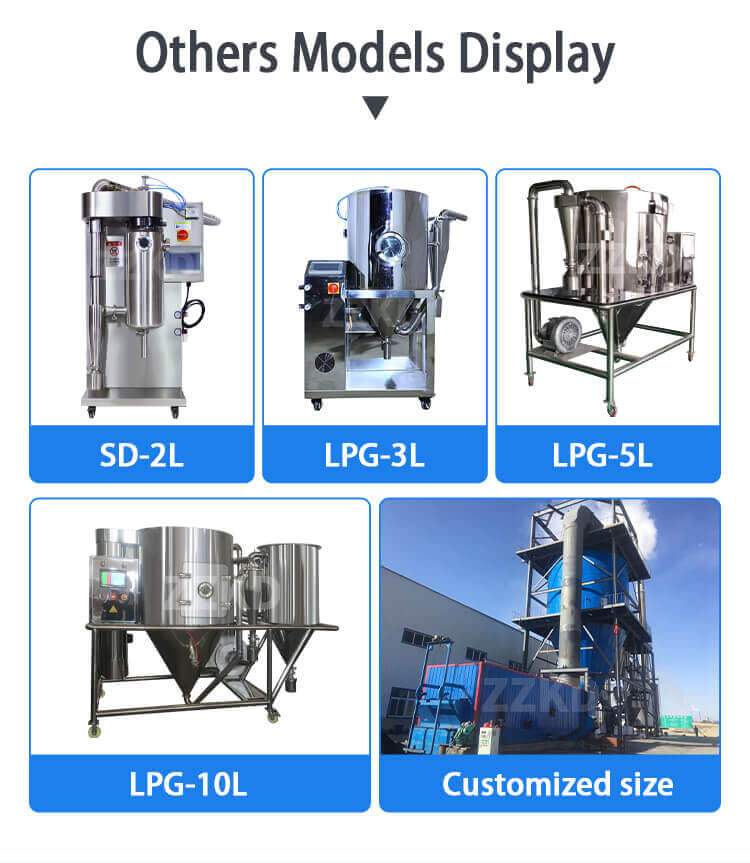

1. ZZKD Machinery’s SD Series Spray Dryer

ZZKD Machinery offers the SD series spray dryers, which are engineered for high efficiency and versatility. These dryers are suitable for a wide range of applications, including pharmaceuticals, food processing, and chemicals. Key features include:

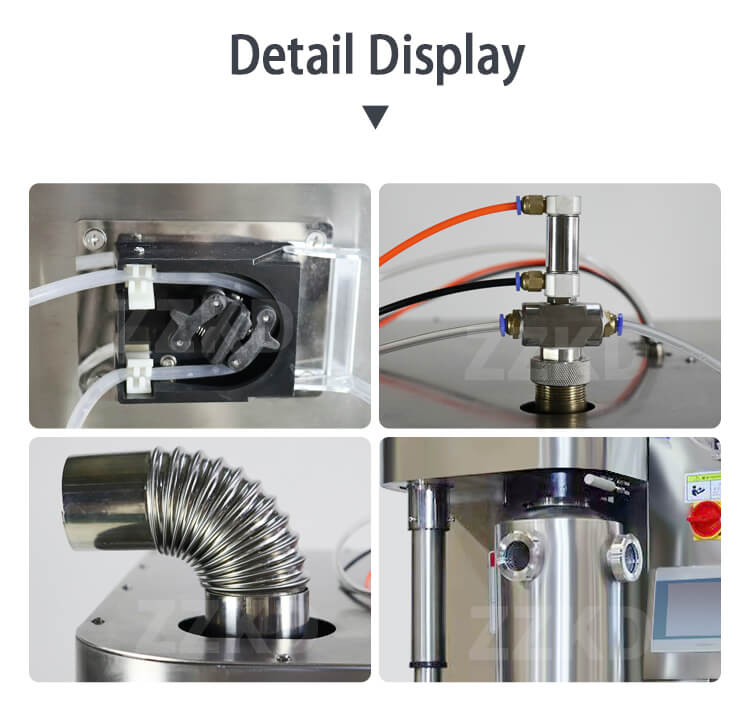

Advanced Atomization Technology: The SD series utilizes high-precision nozzles and rotary atomizers to ensure uniform particle size distribution.

Energy Efficiency: Equipped with state-of-the-art heat recovery systems, these dryers minimize energy consumption while maximizing drying efficiency.

Robust Construction: Made from high-quality stainless steel, the SD series is designed for durability and long service life.

User-Friendly Interface: An intuitive control system with real-time monitoring and adjustable parameters enhances operational ease and product quality.

2. LPG Spray Dryers

LPG is a well-established name in the spray drying industry, known for its innovative solutions and high-performance equipment. The LPG series spray dryers are ideal for a variety of applications, offering:

Customizable Designs: LPG provides tailor-made solutions to meet specific production requirements, ensuring optimal performance and product quality.

Enhanced Safety Features: These dryers come with multiple safety mechanisms to prevent overheating and ensure safe operation.

Hygienic Design: Designed with easy cleaning in mind, LPG spray dryers comply with stringent hygiene standards, making them suitable for food and pharmaceutical industries.

Energy-Efficient Operation: Advanced thermal management systems reduce energy consumption, lowering operational costs.

3. Mini Spray Dryer SD-2L

For laboratory-scale applications, the Mini Spray Dryer SD-2L is a popular choice. It is widely used for research and development in various industries. Key benefits include:

Compact Design: The SD-2L is designed for small-scale production and research purposes, offering a compact and easy-to-use solution.

Versatile Applications: Suitable for drying aqueous solutions, organic solvents, and heat-sensitive materials, the SD-2L is highly versatile.

Easy Operation: An intuitive interface and simple setup make the SD-2L ideal for laboratory use, allowing researchers to focus on their experiments.

High-Quality Output: Despite its small size, the SD-2L delivers high-quality powders with consistent particle size and morphology.

Choosing the Right Spray Dryer Supplier

Selecting a reliable supplier is just as important as choosing the right equipment. Here are some tips to help you find a trustworthy spray dryer supplier:

Reputation: Look for suppliers with a strong reputation and positive customer reviews. A well-established company with a proven track record is more likely to provide quality products and reliable service.

Technical Support: Ensure that the supplier offers comprehensive technical support, including installation, training, and maintenance services.

Customization: A good supplier should be able to customize their equipment to meet your specific needs and production requirements.

After-Sales Service: Reliable after-sales service is crucial for maintaining the performance and longevity of your spray dryer. Choose a supplier that offers prompt and efficient support.

Investing in an industrial spray dryer is a significant decision that can greatly impact your production efficiency and product quality. By understanding the fundamentals of spray drying, considering key factors when selecting equipment, and choosing a reputable supplier, you can ensure that you make a wise investment.

Whether you are looking for a high-capacity industrial spray dryer or a versatile laboratory unit, there are many excellent spray dryers for sale that can meet your needs. Among the top choices, ZZKD Machinery’s SD series stands out for its advanced technology, energy efficiency, and robust construction. Explore the options available, and take the next step in revolutionizing your powder production process with the best industrial spray dryers on the market.